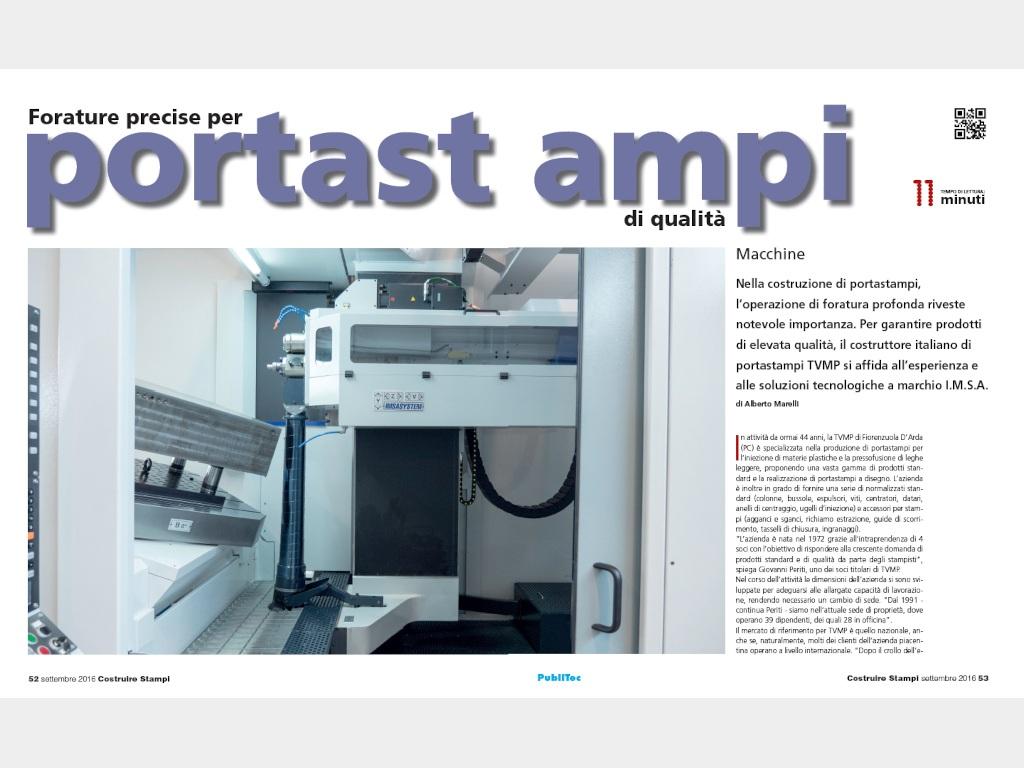

One of the most critical operations in manufacturing mold bases is deep hole drilling. To ensure a high-quality product, TVMP, an Italian manufacturer of mold bases, relies on the experience and technological solutions of I.M.S.A.

Translation of article by the Italian technical journal “COSTRUIRE STAMPI”, September 2016

TVMP is a specialist in the manufacture of mold bases for injection molding of plastic material and die-casting light alloys. Located in Fiorenzuola D’Arda (PC) Italy, it has been in business for 44 years. This company offers a wide range of standard products and engineers custom made mold bases. It is also able to provide a series of standard parts for mold making (support pillars, bushings, ejectors, screws, date stamps, centering units, locating rings, injection nozzles) and mold accessories (latch locks, ejector returns, slide guides, plug inserts, gears).

“The company was created in 1972, thanks to the enterprising spirit of 4 partners, to respond to the growing demand of mold makers for standard and high-quality products,” explains Mr. Giovanni Periti, one of the partners at TVMP.

The company grew over the years to accommodate its increased machining capacities, eventually forcing it to relocate to a larger facility. Mr. Periti continues, “We have been operating out of our same building since 1991, and employ 39 people, of whom 28 are in the workshop.”

Italy is TVMP’s target market, although, of course, many of the Piacenza-based company’s customers operate internationally. “After the 2008-2009 financial crisis, the mold and die industry recovered, regaining its pre-crisis sales levels. The problem is the lack of long-term visibility of future orders, and this makes it difficult to plan the company’s activities: from purchasing material to scheduling work at our facility.”

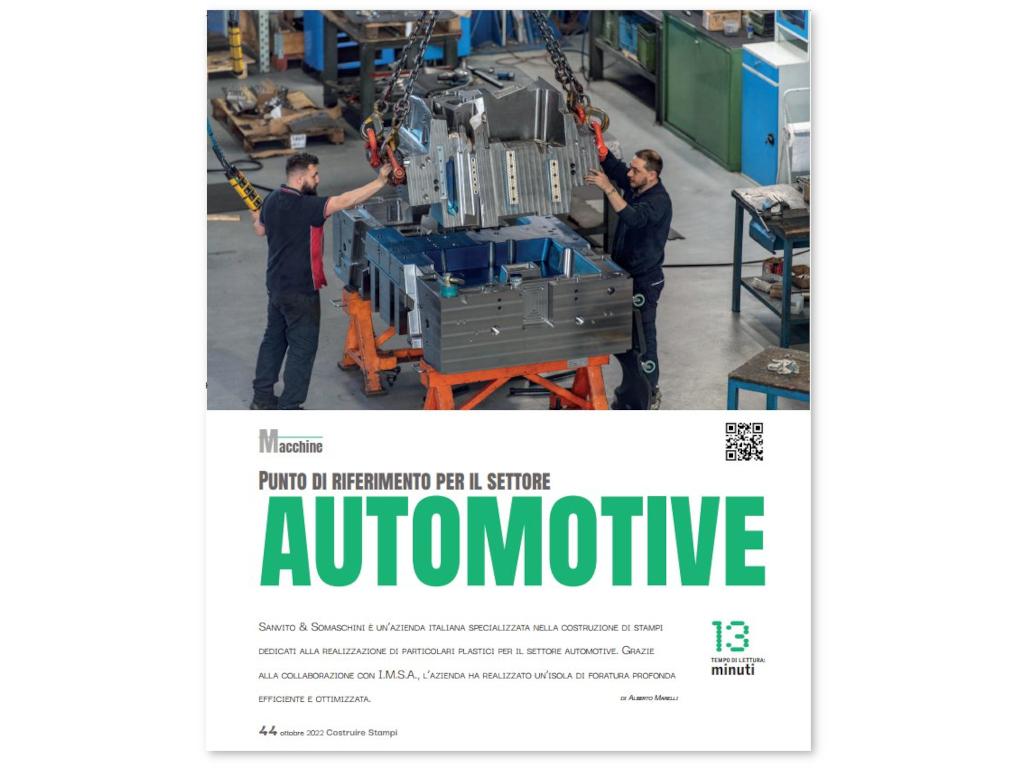

ALL MACHINING OPERATIONS ARE DONE IN-HOUSE

TVMP is now in a position to offer a wide range of custom machining solutions, with a high degree of precision in fabricating cylindrical and angled cavities as well as holes for cooling or heating inserts.

One of the strengths of the company is reflected in the fact that it can handle all machining operations in its production departments. “Through continuous investment in technology, we have always done out best to ensure that our customers are fully satisfied with every TVMP product purchased,” says Mr. Periti.

The company relies on highly specialized personnel and new-generation machine tools: multi-pallet and conventional milling machines, saws for cutting material, grinding machines, deep hole drilling machines and precision machining centers. “Starting with the raw material, we first mill the plate and then deep hole drilling operations for the temperature control system. The roughing operation is the next step, followed by grinding. The plates are then transferred to the machining centers for all of the finishing processes.”

DOUBLE-SPINDLE DEEP HOLE DRILLING MACHINES

A critical part of the production process for the fabrication of a mold base is side-machining the plates. This involves deep hole drilling to create the temperature control system as well as milling operations. “We used radial drilling machines for deep hole drilling operations up until 1996, and then switched to high-performance deep hole drilling machines,” notes Mr. Periti. “The first drilling machine was manufactured by a German company: a machine fitted exclusively with a gun drill head. When I.M.S.A. appeared on the market, it introduced an extremely attractive feature for our application requirements that other machines did not have: a double head for performing deep hole drilling and milling operations. We decided to buy our first I.M.S.A. machine in 2002: the MF 1000BB model, to be precise. Given the high-performance of the machine, we replaced the German manufacturer’s drilling machine in 2007 with a second machine (MF 1000/2F). A few months ago, we purchased our third I.M.S.A. machine, the new MF1250/2FL, so now we can machine even larger plates (the machine can handle rotating a 1900 mm mold weighing up to 6000 kg).”

THE POSSIBILITY OF LIGHTLY ATTENDED MACHINING OPERATIONS

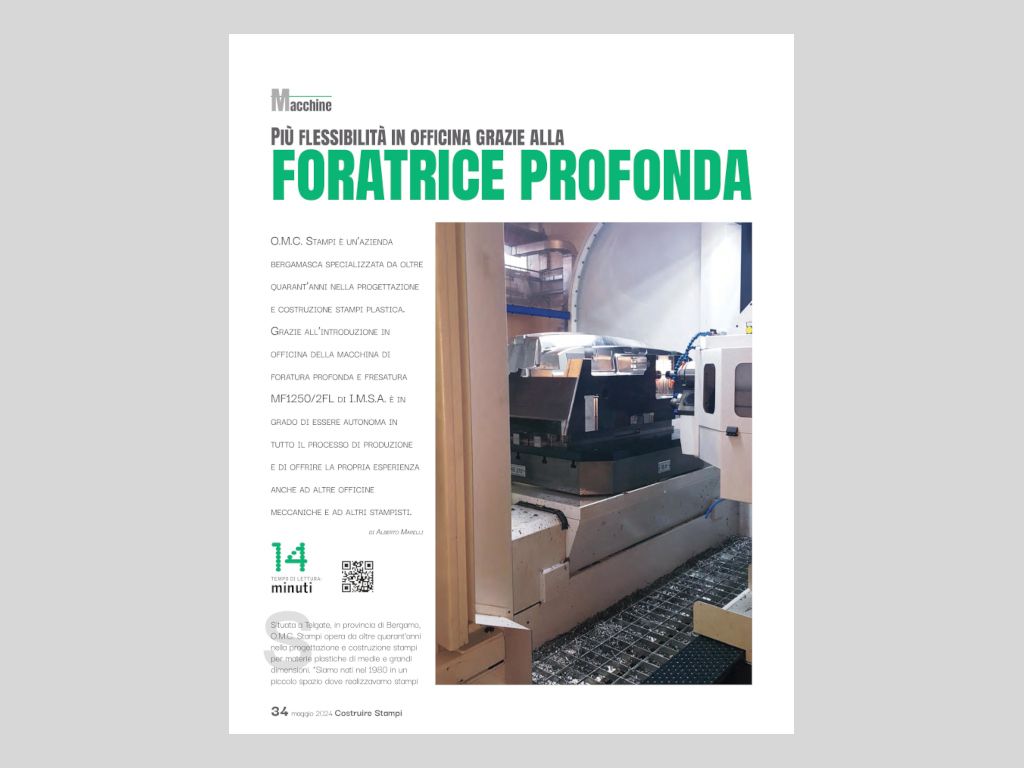

The MF1250/2FL deep hole drilling machine was created with aim of being what can be identified as the “big sister” to the MF1000/2F model launched on the market by I.M.S.A. in 2007.

It is capable of drilling to a depth of 1250 mm in a single operation for gun drilling diameters from 4 to 25 mm, up to 32 mm counterboring or in short-chipping materials. The reliability of the machine makes it possible to operate without requiring continuous operator attendance and to drill many meters of material before the gun drill needs to be re-sharpened.

As mentioned above, the headstock of this model has a dual-spindle configuration: one for gun drilling and one for ancillary milling operations. “Thanks to this feature, we can perform tapping operations or create inlets for cooling lines without having to move the plate to a different machine, thereby saving valuable time,” says Mr. Periti. “Furthermore, the fact that the two spindles are positioned one on top of the other allows us to take advantage of the greater lateral space of the machine to work on larger molds.”

The structure of the MF1250/2FL, larger and reinforced accordingly, continues to have a “shell” shape, is free-standing and does not require foundations; it’s vertical gantry structure, which is 16 times more rigid than traditional structures with columns supported only at the bottom, ensures high performance in any position along the vertical axis. “It is a compact machine with large travels compared to the floor space occupied; naturally, we are extremely pleased with this feature,” explains Mr. Periti. “Another important aspect is its ergonomic design allowing the operator to easily access the work area of the machine so they can perform their work on the mold base.”

5-AXIS MACHINING IS POSSIBLE

A rotary-tilting table is fitted as standard on the MF1250/2FL for 5-axis machining, also with compound-angle drilling.

The machine is equipped with a Heidenhain TNC 640 CNC control with deep drilling cycles specially developed by I.M.S.A. programmers in close collaboration with the CNC manufacturer. I.M.S.A.-specific functions, common to all of I.M.S.A.’s newly constructed drilling machines, are available for controlling the deep drilling process. These functions include the electronic approach to the workpiece, electronic gun drill breakage control by reading the shear stress and a coordinate transformation function for angled machining. A new feature of the 2FL is the use of the RTCP function of the Heidenhain TNC 640 with two useful innovations: one is the use of a single origin point on all four faces of the mold; the second is the automatic compensation of the distance between the two spindles when switching between drilling and milling.

OIL TEMPERATURE CONSTANTLY UNDER 30°C

We will continue exploring the subject of deep hole drilling. Deep hole drilling oil management is extremely important for the quality of results. The oil temperature in MF1250/2FL deep hole drilling machines is maintained under 30°C thanks to a heat exchanger; a highly efficient filter system made of 16 µm non-woven fabric is used for oil clarification; the oil pumping system consists of two variable flow pumps selected by M functions depending on the drilling diameter. An optional oil mist collection system can be provided to ensure a healthy environment.

HIGHER SPINDLE POWER

A number of improvements were made to the new machine design. One of which is the increased power of both the drilling spindle and the milling spindle to 9 kW, a fundamental aspect especially when drilling high-alloy materials; it is useful in the milling motor because it allows for rigid tapping up to M24 and the adoption of large diameter twist drill bits.

Now, let’s move on to the subject of milling. The unit on a separate axis, located above the deep drilling axis on the same slide, makes it possible to prepare and complete the cooling circuit without requiring the presence of an operator to switch from deep drilling to milling operations and vice versa. The ISO 40 milling head has a 9 kW motor with a maximum speed of 4000 rpm. There is also an internal conduit for oil (50 bar) through the tools. The machine is equipped with an ISO tool changer magazine for 12 tools; however, magazines holding 24 to 40 tools are also available.

As regards axis positioning, the MF1250/2FL uses glass scales. The machine is increasingly used to perform pocket milling and precision guides, or for ejector drilling. The precision offered by a positioning system with glass scales for these tasks is significant.

In this machine, everything contributes to ensuring its high degree of autonomy. Under optimal conditions and with conservative cutting parameters, it is possible to drill 30 meters before the gun drill needs to be re-sharpened

The MF1250/2FL deep hole drilling machine delivers the reliability needed to operate without constant operator supervision, making it clear that the autonomy of up to 30 meters of drilling before requiring sharpening in a machine constructed for a medium-sized mold could make it possible to drill the entire cooling circuit without stopping to sharpen the gun drill.

It’s worth noting that the quality of a machine is just one of the aspects TVMP takes into consideration when choosing a machine. “Nowadays, after-sales service is very important and, in this sense, I am very pleased with I.M.S.A.,” says Mr. Periti. “The company has always promptly responded to our requests for help”.