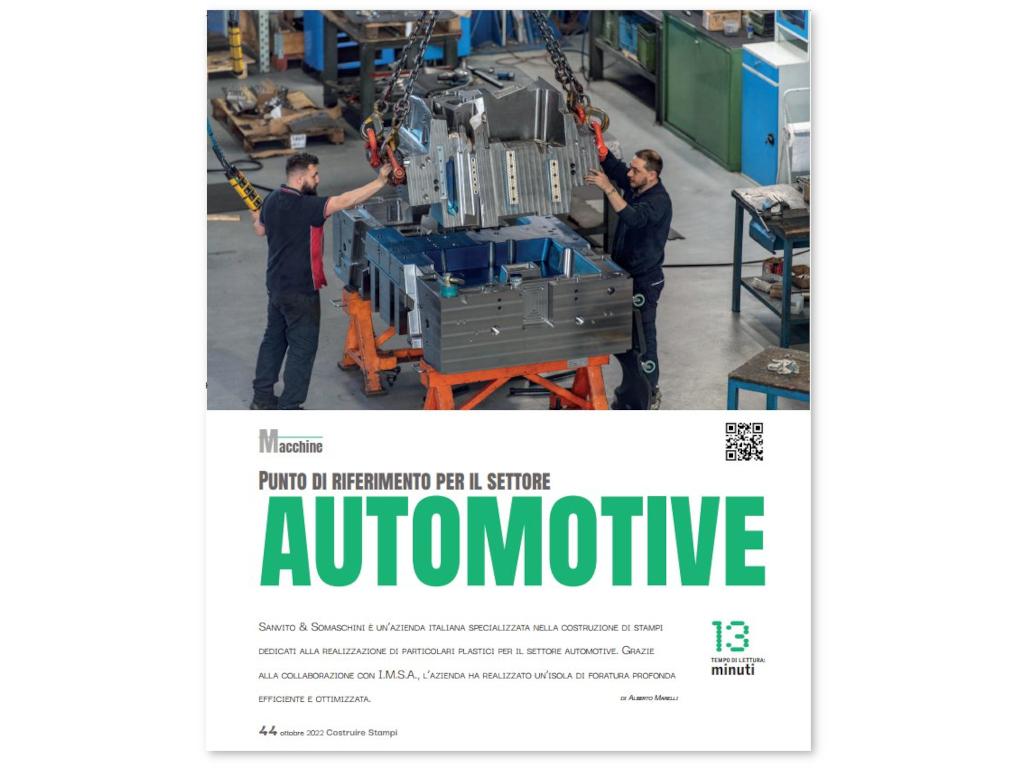

Sanvito & Somaschini is an Italian company specialising in the mold making for the construction of plastic parts for the automotive industry. In cooperation with I.M.S.A., the company realized an efficient and optimized deep drilling cell.

Translation of the article by the Italian technical magazine “COSTRUIRE STAMPI” (published by Publitec) – October 2022

High-quality standards, reliability, flexibility and continuous investment in technology: this is the philosophy that has inspired Sanvito & Somaschini since its foundation and that, after over 50 years of history, has allowed the company to continue evolving in line with the needs of the global automotive market.

Sanvito & Somaschini is a leading manufacturer of moulds to produce plastic parts for the automotive industry, and works with leading companies like BMW, Stellantis, Volkswagen, Automotive Lighting, Flex n Gate, Magna, and Plastic Omnium.

The moulds developed in-house at Sanvito & Somaschini enable the production of plastic components with a high aesthetic value, according to constantly high quality standards throughout the equipment lifecycle.

The construction of large moulds, today the company’s core business, has complemented the original light mould construction business for many years. This choice allowed the company to expand its range of products and conquer a leading role in the international market.

“We can make any type of plastic mould, from bumpers to side panels, from spoilers to bonnet grilles, highly complex headlights and lights” – explains Salvatore Morreale, Plant Manager at Sanvito & Somaschini.

Founded in 1968 by Alfredo Sanvito and Giuseppe Somaschini, the company has grown steadily, both in terms of machinery and personnel. Since 2014, the second generation of Sanvito & Somaschini has succeeded the two founding partners in running the company, ensuring continuity, stability and modernity to the business.

“Today, Sanvito & Somaschini is one of the largest mould makers in Italy to offer a complete service, from design and co-design to optimized try-out, from machining to the most particular finishes, from the selection of the best raw materials to the assembly of each smallest component, to finalize accurate, reliable and durable moulds. This is why customers choose us” – Morreale pointed out.

TWO SITES FOR PRODUCTION ACTIVITIES

Sanvito & Somaschini operate two plants in the area of Northern Italy called Brianza: the historical site of Carate Brianza, where all milling activities are carried out, and the Renate site, where most of the engineering, assembling and testing activities are completed (with four presses with capacities of 1,000, 2,300, 4,000 and 4,500 tons).

“Sanvito & Somaschini’s moulds are unique pieces that combine the precision of state-of-the-art technology with the experience and know-how of a highly skilled workforce. Each mould is designed and manufactured to meet the most demanding production requirements, maintaining high quality and reliable performance and results throughout the entire lifecycle” – said Morreale.

The lead time of a large-size mould is extremely important for the Sanvito & Somaschini team.

“In the past, we used to make a mould in 22 weeks; today we can make moulds in as little as 14 weeks. I think this is the trump card for this type of product” – said Morreale.

Constant investments in R&D enabled Sanvito & Somaschini to organize a highly qualified design department that works closely with its partners at every stage of co-design, analysis and feasibility, to achieve the highest quality standards in the shortest possible time.

The main machining operations take place in the over 5,500 sq.m. factory located in Carate Brianza, starting with the roughing of the steel blocks, which gives the first shape to the mould, and passing through semi-finishing and finishing, drilling and erosion processes.

“We work two shifts, but the machines are equipped to work nights and weekends” – explained Morreale.

The moulds, whether large-size pieces or for the lighting division, are then transferred to Renate, where specialized teams are dedicated to the assembly phase, determining the final appearance of the mould and all its components.

Each step of mechanical machining is supervised by the Metrology Department. “We check compliance with quality standards of anything we produce internally and receive from our partners, from the raw material to the semi-finished product, from the finished mould to the entire testing process, with the aim of ensuring the best performance of the mould during its production cycle” – said Morreale.

The management of Sanvito & Somaschini is planning a 6,000 sq.m. extension of the production departments of the Carate Brianza site.

A DEEP DRILLING ISLAND WAS CREATED TOGETHER WITH I.M.S.A.

In the tooling shop, an important part of daily activities consist in deep drilling operations. To ensure maximum efficiency in the department, Salvatore Morreale and his team created, together with I.M.S.A., a deep drilling island.

“We arranged the machines in such a way that access to the equipment is always towards the inside of the cell; this facilitates the workflow.”

The deep drilling island contains 4 I.M.S.A. machines: MF 1000 BB, MF 1500 BB/2, MF 2000 BB and the newly-installed MF 1250/2FL.

“Our collaboration with I.M.S.A. began in 1997 with the purchase of the first drilling machine and continued with the second purchase in 2002; both machines were later replaced by more advanced models. Over the 25 years of our relationship with I.M.S.A., we have observed a continuous product evolution that allowed us to remain competitive. We like to think of our deep-drilling department as an I.M.S.A. department”’ stressed Morreale with satisfaction.

In addition to being an I.M.S.A. customer, Sanvito & Somaschini is also an important technology partner that, thanks to its experience and expertise, collaborates with the manufacturer. “Models proposed by I.M.S.A. over the years have been designed following some of our technical specifications. This benefited both companies: we always purchased ‘customized’ machines, built exactly to our specific requirements, while I.M.S.A. could market these models on a large scale” – said Morreale.

The tooling shop is equipped with I.M.S.A. deep drilling machines of different sizes that allow Sanvito & Somaschini to meet most deep drilling requirements.

A RETROFITTING PERFORMED

Recently, I.M.S.A. carried out retrofitting work on the MF 1500 BB/2 deep drilling machine purchased from Sanvito & Somaschini in 2004.

“Thanks to I.M.S.A.’s intervention, the table was replaced and the milling line was upgraded. It was not thinkable to reach the state of the art because it was made impossible by certain aspects, but we can secure this machine another 10-15 years of good operation”.

Nowadays, when choosing a machine tool, product quality is just one of the parameters that a company takes in consideration.

“After-sales service has become crucial. I.M.S.A. ensures high quality in this area, too. We have always found that this company is close to the customer. The business and human relationship created with I.M.S.A. engineers and partners is really important. And the willingness to retrofit the machine is also one of the reasons why our cooperation continuing” – concluded Morreale.

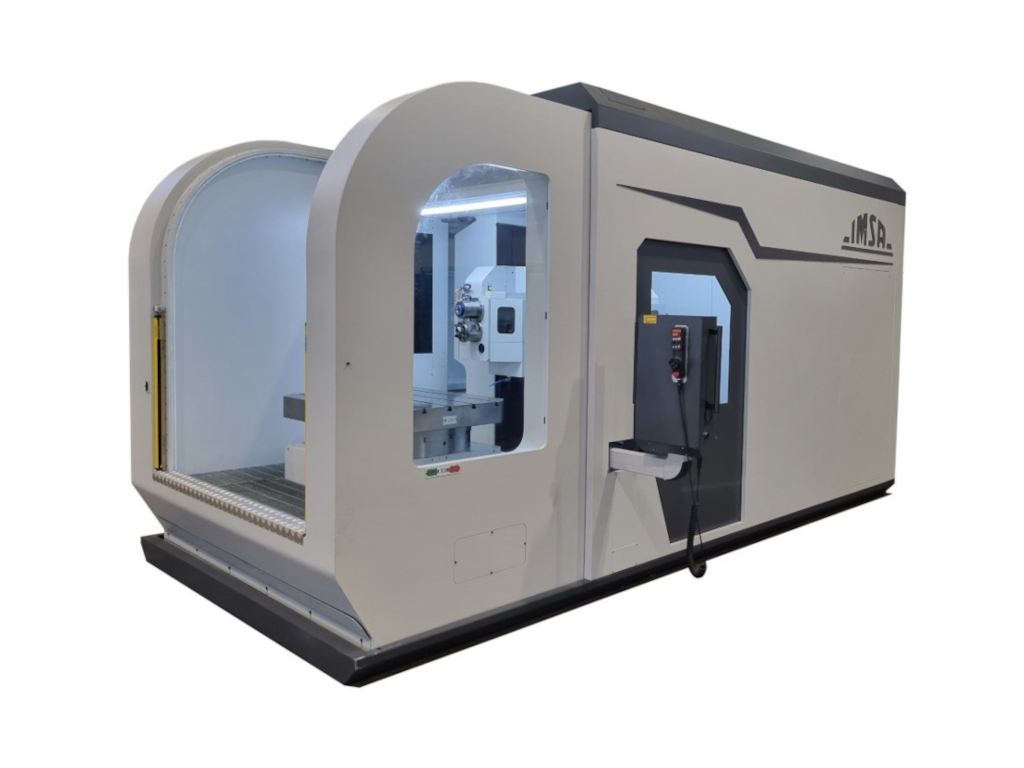

DETAIL: MF1250/2FL FOR MEDIUM-SIZED MOULDS

The latest addition to the Sanvito & Somaschini deep drilling island is the I.M.S.A. deep drilling and milling machine MF1250/2FL. This machine is suitable for moulds of up to 6 tonnes. The reliability of the machine ensures work without the constant presence of an operator (unattended) and the drilling of many metres before the gun drill needs to be sharpened.

The headstock accepts both spindle lines: deep drilling and milling on a separate unit, automatically switching from one another in a few seconds. This machine boasts a unique approach to achieve compound angle holes. Having the table tipping pivot and turning toward the ram, extremely complex cooling circuits can be drilled from a single positioning exploiting the machine’s full vertical stroke.

The MF1250/2FL’s structure is a self-supporting “shell” that does not require foundations; it features a vertical gantry column, which provides sixteen times the rigidity of an equivalent lower-guided column structure, enabling high performance in any position along the vertical. It is a compact machine with large travels respect to its overall dimensions (X 1700 mm, Y 800 mm, workpiece table 1000 x 1000 mm).

As well as deep holes for cooling circuits, it enables different types of milling on the “mechanics” of the mould, like squaring, slots, shallow holes, holes for ejectors, threads and so on.