O.M.C. Stampi is a Bergamo-based company that has specialized in plastic mold design and construction for over forty years. Thanks to the introduction of I.M.S.A.’s MF1250/2FL deep-drilling and milling machine into the workshop, it is able to be autonomous in the entire production process and to offer its expertise to other machine shops and moldmakers.

Translation of the article by the Italian technical magazine “COSTRUIRE STAMPI” (published by Publitec) – May 2024

Located in Telgate (near Bergamo in northern Italy), O.M.C. Stampi has been in the industry for over four decades in designing and building medium and large molds for plastic injection.

“My company was established in 1980 in a small space where we primarily produced molds for the fashion accessories sector (buttons, buckles and hangers). It was an extremely artisanal activity where the pantograph was used a lot,” explains Emanuele Pesenti, founder and owner of the company. “After a short period we decided to leave the fashion sector and enter the plastic industry. We initially focused on molds for the children’s segment, and then over the years we expanded our target sectors: high-end design and furniture, packaging (e.g., accessories for coffee machines and capsules, packaging for hospital waste, etc.), automotive, housewares, and lighting engineering, just to name a few,” Pesenti says.

After five years, the company relocated to a 600-square-meter facility in to Grumello del Monte (near Bergamo). “We began investing in our first CNC milling machines, which complemented the large die-sinking EDM equipment we used for all our mold couplings,” Pesenti points out.

Another significant milestone for O.M.C. Stampi occurred in 1993, when the company moved to its current site, significantly increasing its floor space.

“After our latest move we have continued to purchase new CNC machines and equipment,” Pesenti states.

“Our large and technologically advanced milling department enables us to rough-cut and machine large parts up to 1,800×3,500 mm. For finishing operations, state-of-the-art 3- and 5-axis machining centers are installed for machining parts up to 2,000×1,000 mm,” says Silvio Pesenti, son of the owner and Production Manager.

“Our shop is also equipped with plunge and wire EDMs for machining large blocks up to 2,300×1,500 mm, as well as a deep milling and drilling machine, a CNC lathe, and a micro-drilling machine.”

OMC STAMPI has a mold assembly and maintenance department that consists of three operating stations, each served by its own overhead crane, which can therefore work autonomously and independently of other workshop areas. A mold testing press serves the assembly department.

“Human resources are the strong point of the assembly/maintenance department. Qualified and experienced personnel ensure the optimal combination of the activities carried out by all other departments. Assembly may seem to be the least technologically advanced phase, but it is actually the most critical one for the production of injection molds for plastics,” says Emanuele Pesenti.

Reliable molds

Over the years, O.M.C. Stampi has specialized in the production of high-quality injection molds for plastics, mainly in steel, but also in aluminum, both for high-volume production and limited series.

“Regardless of the industry, customers turn to us for the special care, high technology and high-level superficial finishes of our molds. Our customers know they can find in us a reliable partner to work with to achieve the highest product quality within the required timeframe,” says Alessandra Pesenti, daughter of the owner and the company’s sales manager.

“We can boast extensive experience in the field of designing and manufacturing high-quality injection molds for the production of plastic parts wish special aesthetic and structural requirements,” the founder interjects.

“The know-how acquired over the years gives us the ability to make equipment that complies with our customers’ needs and guarantees large production runs with minimal maintenance. The technologies implemented over time in our shop floor equipment make us completely autonomous in project implementation.”

The company developed an innovative molding technology, called SPS (Simultaneous Pluri-injection System) Technology.

“We developed and experimented with this injection technique to achieve unique, original color combinations and color effects in the molded objects with the special feature of being repeatable,” explains Emanuele Pesenti. “By choosing the colors and the type of pattern to be made, all the molded objects with the same settings will be very similar to each other, yet never repeat completely identically. The effect is a predetermined randomness, the right combination of uniqueness and standardization. Each printed object will be unique. Its peculiarities make this technology suitable for application to a variety of commodity sectors, with a special focus on design objects.”

Full service from idea to object

Before the manufacturing, O.M.C. Stampi takes care of the design, also thanks to the cooperation with two external design offices.

“We offer customers a complete service from idea to object. We accompany our clients in all stages of mold making: product engineering, co-design, design, construction and sampling,” explains Silvio Pesenti.

The internal technical department covers design and customer service in addition to in-process modifications, which are usually urgent.

“Our machine shop constantly gets updated and renewed, as well as the application used, to always achieve the required quality and precision. Cutting-edge technologies, Industry 4.0, interconnection and high professionalism are additional pieces of the puzzle that make up an excellent end result,” says Silvio Pesenti. “All the latest milling machines and the deep-drilling equipment are connected to the WorkPLAN management system in order to control the entire production process, from quotation to mold making.”

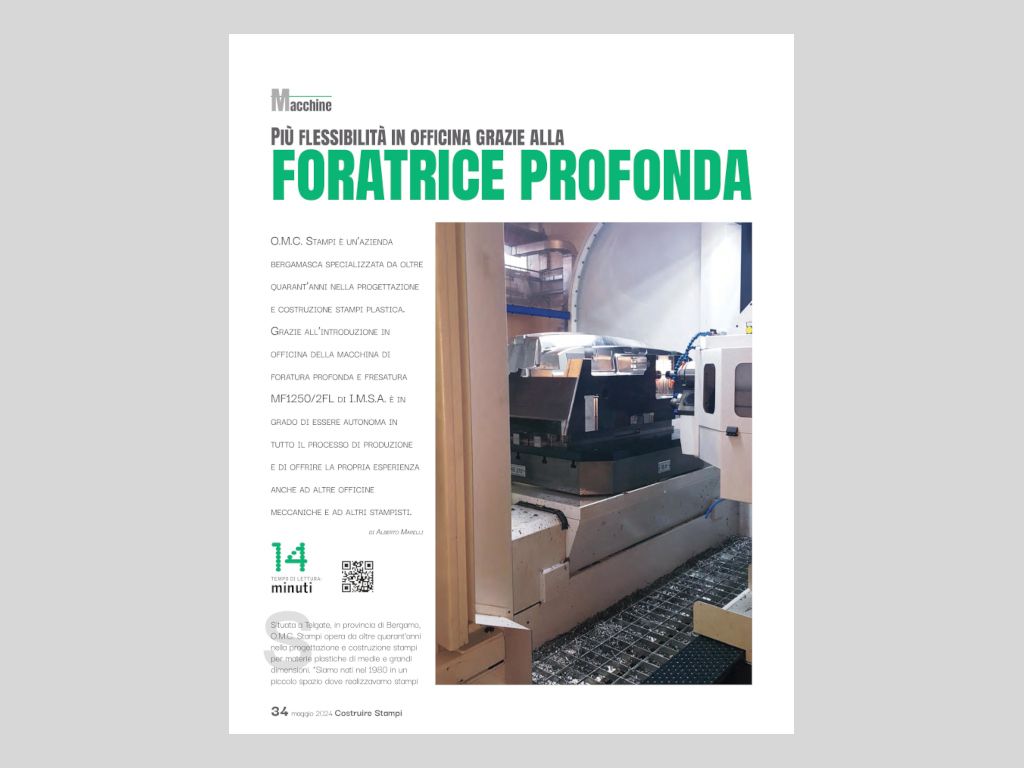

Gun drilling also as job shop

In 2017 O.M.C. Stampi added to its production department a 5-axis deep hole drilling and milling machine, namely a MF1250/2FL by Italian manufacturer I.M.S.A.

Deep drilling is indeed one of the first machining operations to be performed in the manufacturing of plastic injection molds, a sort of base from which all the rest is built.

““The introduction of the I.M.S.A. machine in our workshops has enabled us to be autonomous in the whole production process and to enter the market of machining as subcontractors, offering our experience to other machine shops and mold makers,” says the founder of O.M.C. STAMPI.

“After analyzing the solutions on the market, we chose the I.M.S.A. brand as the most reliable partner, not only in terms of machine construction quality, but also in terms of after-sales services,” Silvio Pesenti points out. “All the companies using I.M.S.A. machines that we’ve interfaced with have always confirmed the quality of these machines.”

O.M.C. Stampi is currently equipped to perform deep drilling on molds and blocks up to 6 t in weight.

The achievable 5-axis holes reach up to 30 mm in diameter and 1,250 mm in depth.

“MF1250/2FL is the model that both dimensionally and cost-effectively allows us to meet our work requirements as much as possible,” says Silvio Pesenti.

“It is an extremely reliable machine (in both drilling and milling operations), precise and performing,” intervenes Emanuele Pesenti. “It solves many design-related problems for us as we can precisely make holes in certain positions and inclinations, also limiting drilling hours as we go to drill in the exact spot where it is needed. Thanks to I.M.S.A. MF1250/2FL, we have drilled thousands of holes in H7 tolerance, an aspect that is not so obvious. We are also able to machine hardened steels with hardness up to 50 HRC.”

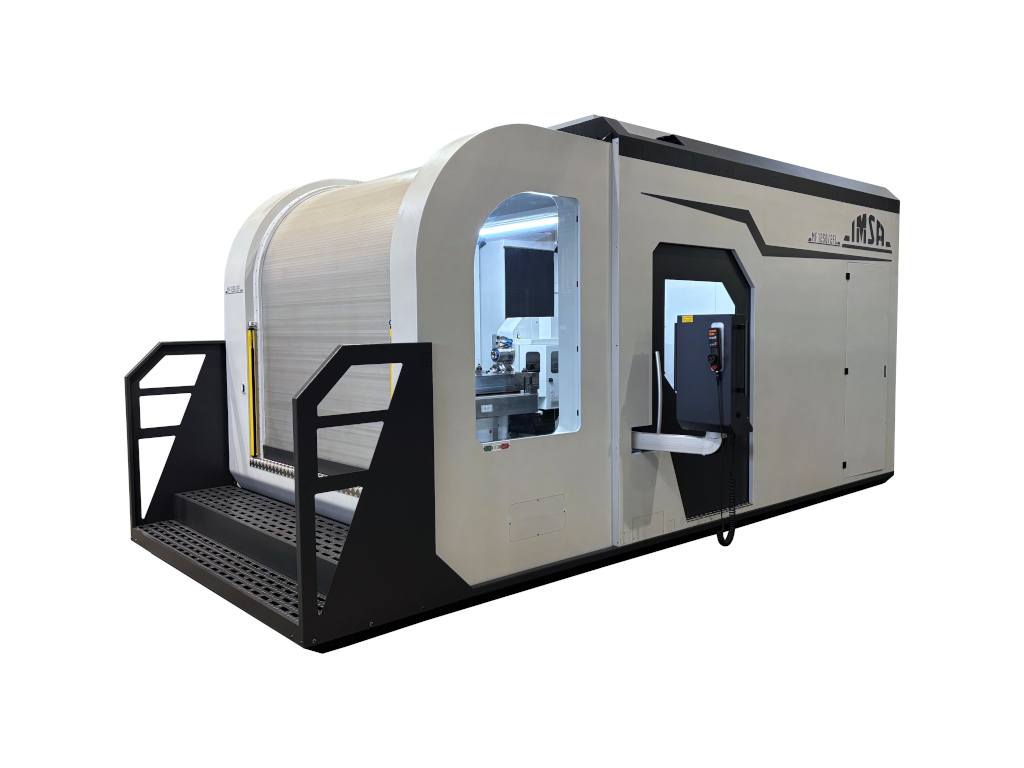

Self-supporting structure requires no foundation

As mentioned above, the MF1250/2FL gun drilling and milling machine by I.M.S.A. is suitable for molds up to 6 t. Its reliability ensures that it can work without a constant operators’ presence and perform many meters of drilling before the drill cutting edge needs to be sharpened.

The headstock accommodates both spindle lines: gun drilling and milling on separate axes, switching over fully automatically in seconds. A unique solution for handling compound-angle holes with a rotary/tilting table that has an advanced pivot-point towards the headstock. Thanks to this solution, extremely complex water lines are carried out with a single workpiece setup and utilizing the entire vertical travel.

MF1250/2FL has a self-supporting “shell” structure that requires no foundation work; it features a vertical gantry column, a guarantee of 16x higher rigidity than a similar movable column structure, allowing high performance in any position along the vertical travel. This is a compact machine with long travels in respect to its workshop footprint (X 1.700 mm, Y 800 mm, table size 1.000×1.000 mm).

As well as deep holes for the cooling circuit, it performs the different milling operations on the “mechanics” of the mold, such as squaring, pocket milling, drilling by twist drills, ejector holes, threads and so on.

The MF1250/2FL gun drill has a 11 kW, 6000 rpm drilling spindle, to drill diameters from 4 to 25 mm from solid, and up to 32 mm in counter-boring, for a maximum drilling depth of 1250 mm.

The milling spindle has a power of 13 kW, torque 115 Nm, maximum speed 6,000 rpm. In addition to external air and oil cooling by nozzles, it is equipped with internal oil flow circuit up to 50 bar as standard.

Like in other I.M.S.A. machines, special care is given to oil management. In the MF1250/2FL gun drill, oil temperature is kept constantly below 30 °C by a heat exchanger; clarification is handled by a deep bed non-vowen 16 µm filtering system; oil pumping is performed by two variable-flow pumps selected by M functions depending on the drilling diameter.

Specific functions control the gun drilling process

MF1250/2FL is equipped with Heidenhain TNC 640 control with deep drilling cycles expressly developed by I.M.S.A. programmers in close cooperation with the CNC manufacturer.

Specific functions, common to all the newly developed I.M.S.A. machines, control the gun drilling process, namely: electronic approach to the workpiece, electronic control against gun drill breakage by reading the cutting efforts, coordinate transformation for inclined machining.

Also worth noting is Heidenhain’s RTCP of the TNC 640 control with two useful tools: one is the use of a single origin on the four faces of the mold; the second is the automatic compensation of the distance between the two spindles in drilling/milling switching.

Generational handover

Looking ahead, there will be important news at O.M.C. Stampi.

“My sons are now actively involved in the company’s activities, so we will begin to pass the business from one generation to the next, prepared to face the challenges of the future,” concludes Emanuele Pesenti.

“We also need to consider the purchase of a larger deep drilling machine, again branded I.M.S.A. Before that, however, it is necessary to keep an eye on market trends, which are extremely fluctuating at the moment. We are working on very important projects in various industries that we hope will be able to start by the end of the year.”

Visit O.M.C. STAMPI website: https://www.omcstampi.com/