Mould Solutions has been operating in Maniago, in Friuli Italy, for over forty years. It is a dynamic company specialising in the design and manufacturing of injection moulds for plastics and thermosetting materials. The company relies on the MF1250/2FL gun drilling machine from Italian manufacturer I.M.S.A. to make the cooling circuits for the moulds.

Translation of the article published by the Italian technical magazine “Costruire Stampi”, March 2021

Product quality and flexibility: these are the principles of operation of Mould Solutions, an Italian Friuli-based company specialising in the design and manufacturing of injection moulds for plastics and thermosetting materials.

“In order to offer our Customers a more competitive service and to better meet their needs, we have designed a customised manufacturing scheduling system that is extremely flexible and interconnected to all machining centres to manage scheduling changes in real time due to new requirements or special requests from customers. This is certainly one of our strengths as recognised by our customers, both nationally and internationally,” says Luca Favetta, who, in addition to being Managing Partner of Mould Solutions, also holds the position of Sales Manager.

Mould Solutions is a dynamic company born from the merger of two historical companies in the mould sector in the North-East of Italy: De Val Tecnostampi and Mould Service.

De Val Tecnostampi was founded at the end of the 1970s as a small tool shop for the manufacturing of injection and die-casting moulds. The focus on technology investments, the know-how acquired, the innovation and the search for an organisational model capable of guaranteeing customers a complete service, in the nineties led to the establishment of Mould Service, a company specialising in testing injection moulds and moulding of technical parts, initially as a support for De Val Tecnostampi’s in-house mould manufacturing and later expanding the service to third parties.

“The idea of merging the two companies stems from market requirements, the implementation of synergies and the optimisation of resources, in order to continue offering customers a technically and qualitatively valid product, with a view towards future development and continuity,” explains Favetta.

Today, Mould Solutions is a solid business consisting in a staff of 40 people and a manufacturing featuring two factories with a surface area of 4,500 square metres.

A 4.0 COMPANY

Mould Solutions features machinery and equipment in line with the latest technology: 3- and 5-axis high-speed milling machines equipped with pallet changers, wire and die-sinking EDM equipment, a deep hole drilling machine and a laser welding station.

Mould Solutions is a company geared towards digitalisation.

“We have designed and developed an ad hoc 4.0 management system through the cooperation with a software company, starting with production planning and scheduling, and we are currently integrating it with the rest of the company departments,” says Favetta.

The experience gained over the years allows the Friuli-based company to provide a complete service to its customers.

“Our ‘one stop shop’ model is a guarantee for a complete service for our customers: from co-design to the delivery of the mould tested in-house and ‘ready to manufacture’. In order to meet these requirements, we have a press department for mould and die testing. Each press is equipped with a robot for automatic picking and simulation of series production and with a side draw for two-component moulding. In addition to the in-house technical support department, the moulding department offers mould testing and sampling service for third parties and the production of pre-series or small batches,” says Favetta.

COMPLEX MOULDS FOR THE AUTOMOTIVE SECTOR

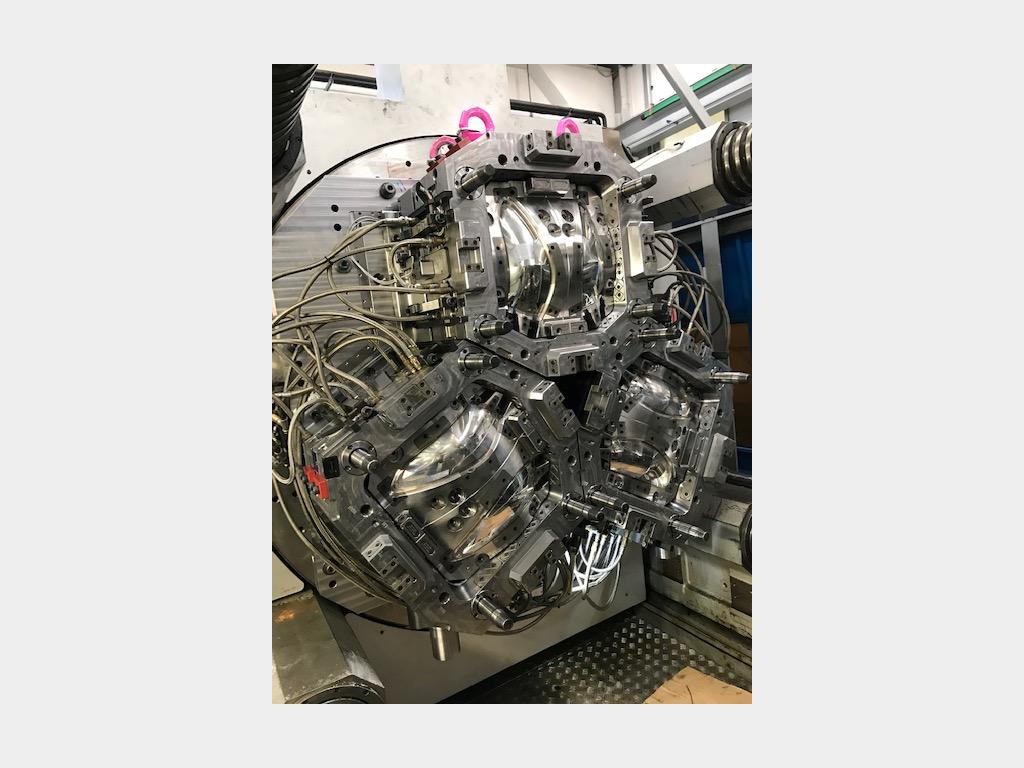

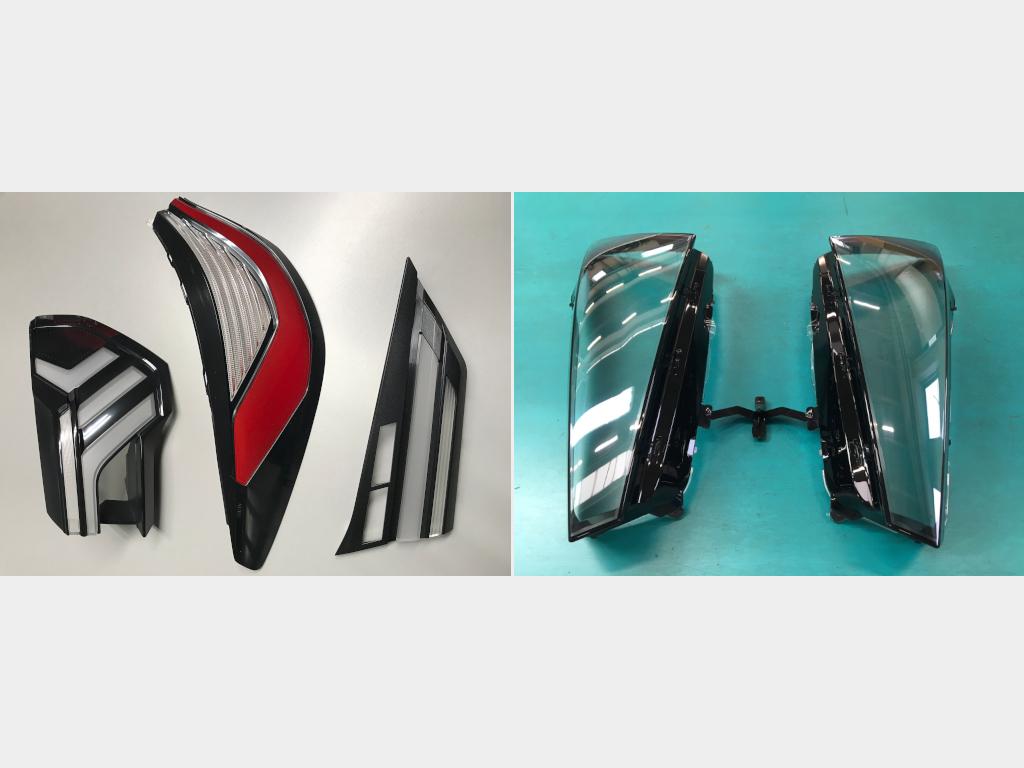

The current focus of Mould Solutions is on the construction of complex medium and large moulds (up to 2,000×2,000×1,500 mm with weights of up to 25 t) for the automotive sector and on multi-component moulds in general: front and rear lights (lenses, frames, reflectors), interior and exterior aesthetic details, air conditioning, front grilles, under windscreen, spoilers, manifolds, handles, centre consoles, glove compartments, side panels and mouldings.

“Sometimes we develop alternative projects to the automotive sector: last year, for example, we made polycarbonate Droplet barriers, which are used to maintain the safety distance for the Covid-19 emergency,” says Favetta. “In the past, we also served the household appliance sector, a sector that we have temporarily reduced in size to accommodate the growing volume in the automotive sector”.

All Mould Solutions’ automotive customers handle mid-to-high-end projects, featuring brands such as BMW, Mercedes, Audi, and Porsche.

“The technology and the special nature of automotive lights in this market niche obviously call for very complex moulds. All this represents an added value that our company can offer to the market,” says Favetta.

HIGHLY DEMANDING COOLING CIRCUITS

When making moulds for highly aesthetic parts, cooling circuits must also be proportionate and adapted to the moulding requirements. This is why Mould Solution purchased the MF1250/2FL deep hole drilling machine from I.M.S.A. last year.

“In the automotive lighting sector, the mould cooling system is very demanding, the holes are very close to each other and therefore the use of an accurate machine helps to reduce the chance of errors and non-conformity during the machining phase. Cooling channels are fundamental to contain deformations, especially when two different materials come together. This is a very important aspect for us and this is what led us to choose the I.M.S.A. machine,” says Favetta.

The MF1250/2FL deep hole drilling machine is not the first I.M.S.A. machine purchased by Mould Solutions. The Friuli-based company began working with I.M.S.A. in 2009 with the introduction of the MF1000BB model.

“With the purchase of the first I.M.S.A. deep hole drilling machine, we have made an important quality leap,” says Favetta. “At that time, not everyone had a drilling machine to create the mould cooling channels. With the MF1000BB we were able to speed up and improve efficiency in the mould manufacturing process.

When we chose to replace the MF1000BB with a larger model last year, it was only natural to turn to I.M.S.A. again, and in particular to the MF1250/2FL machine model.

Thanks to this I.M.S.A. drilling machine we have been able to further reduce the mold lead time, proving that it is an efficient and fast machine that fully meets our manufacturing requirements”.

UNMANNED WORK IS POSSIBLE

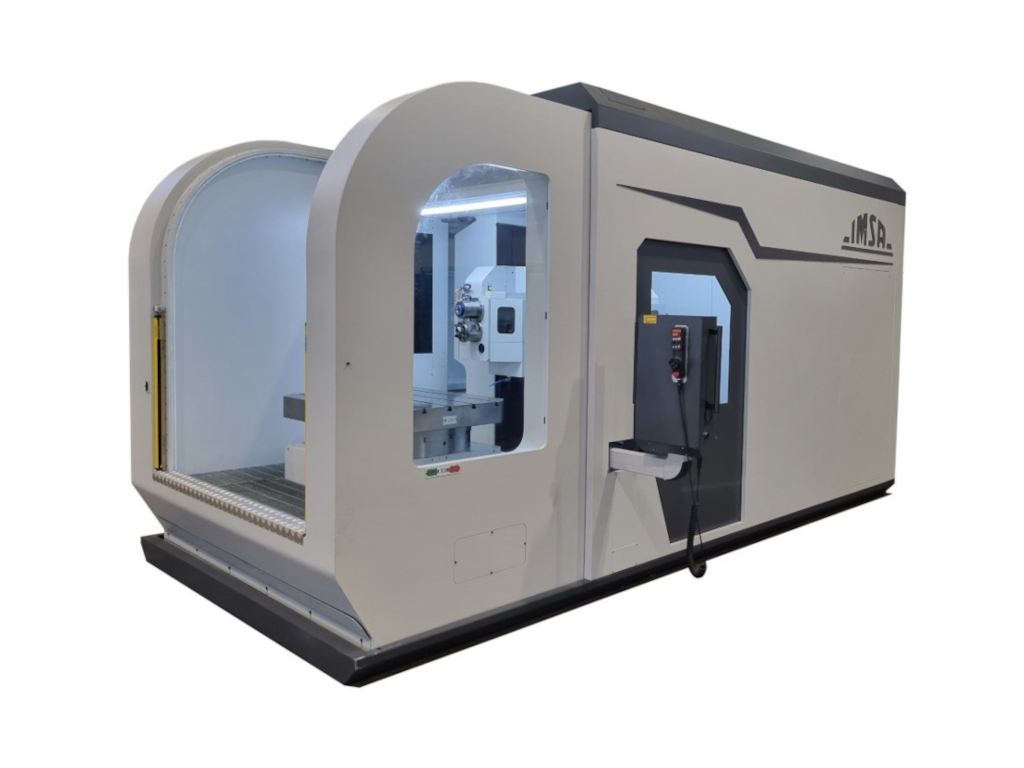

The MF1250/2FL deep hole drilling and milling machine from I.M.S.A. is suitable for moulds of up to 6 tonnes. The reliability of the machine ensures that it can work without the constant presence of an operator and that it can drill many metres before the gun drill needs to be sharpened.

The ram accepts both spindle lines: deep drilling and milling on a separate unit, automatically switching from one another in a few seconds. This machine has a unique approach to achieve compound angle holes. Having the table tipping pivot and turning toward the ram, complex cooling circuits can be drilled from a single positioning, exploiting the machine’s full vertical and horizontal stroke.

The MF1250/2FL’s structure is a self-supporting “shell” that does not require foundations; it features a vertical gantry mast, which provides sixteen times the rigidity of an equivalent mobile mast structure, enabling high performance in any position along the vertical. It is a compact machine with large strokes respect to its overall dimensions (X 1,700 mm, Y 800 mm, workpiece table 1,000 x 1,000 mm).

As well as deep holes for cooling circuits, it enables different types of milling on the “mechanics” of the mould, like squaring, slots, shallow holes, holes for ejectors, threads and so on.

“This characteristic – says Favetta – shortens mould manufacturing time and also minimises the transfer between workshop machines”.

The MF1250/2FL drilling machine has an 11 kW deep drilling spindle with 6,000 rpm for drilling diameters from 4 to 25 mm from solid material, and counter-boring of up to 32 mm, with a maximum depth of 1,250 mm.

The milling spindle has 13 kW power, 115 Nm torque and a maximum rotation speed of 6,000 rpm. In addition to external air and through-nozzle oil-cooling, it comes equipped with a 50 bar internal oil circuit as standard.

As with other I.M.S.A. machines, special care is taken with oil management. In the MF1250/2FL drilling machine, the oil temperature is kept constantly below 30°C by a heat exchanger; clarification is carried out by a high-shear system with 16 µm non-woven fabric; the oil is pumped by two variable capacity pumps selected by M functions according to the drilling diameter.

SPECIALLY DESIGNED DEEP DRILLING CYCLES

The MF1250/2FL drilling machine is equipped with a Heidenhain TNC 640 control system with deep drilling cycles specially developed by I.M.S.A. programmers in close cooperation with the CNC manufacturer.

Specific I.M.S.A. functions are available for controlling the deep drilling process, common to all I.M.S.A. drilling machines of recent production, namely: electronic approach to the workpiece, electronic control against drill breakage by reading the cutting force and the function for adjusting coordinates for sloped machining. Also noteworthy is the use of the RTCP of the Heidenhain TNC 640 control system with two useful tools: one is the use of a single origin on the four faces of the mould; the second is the automatic compensation of the distance between the two spindles in the drilling/milling switch-over.

NOT ONLY PRODUCTS… BUT ALSO SERVICE

Nowadays, when choosing a tooling machine, product quality is just one of the parameters that a company takes in consideration. “After-sales service has become crucial. Here too, I.M.S.A. guarantees high quality: we have always found a company willing to help to solve our problems.

The positive aspect of working with I.M.S.A. is its customer-centric approach, the excellent relationship that is created with I.M.S.A. technicians and contractors. For us, this is an added value that has certainly influenced the purchase of the new machine,” explains Favetta.