SINGLE-SPINDLE

GUN DRILL TOOL

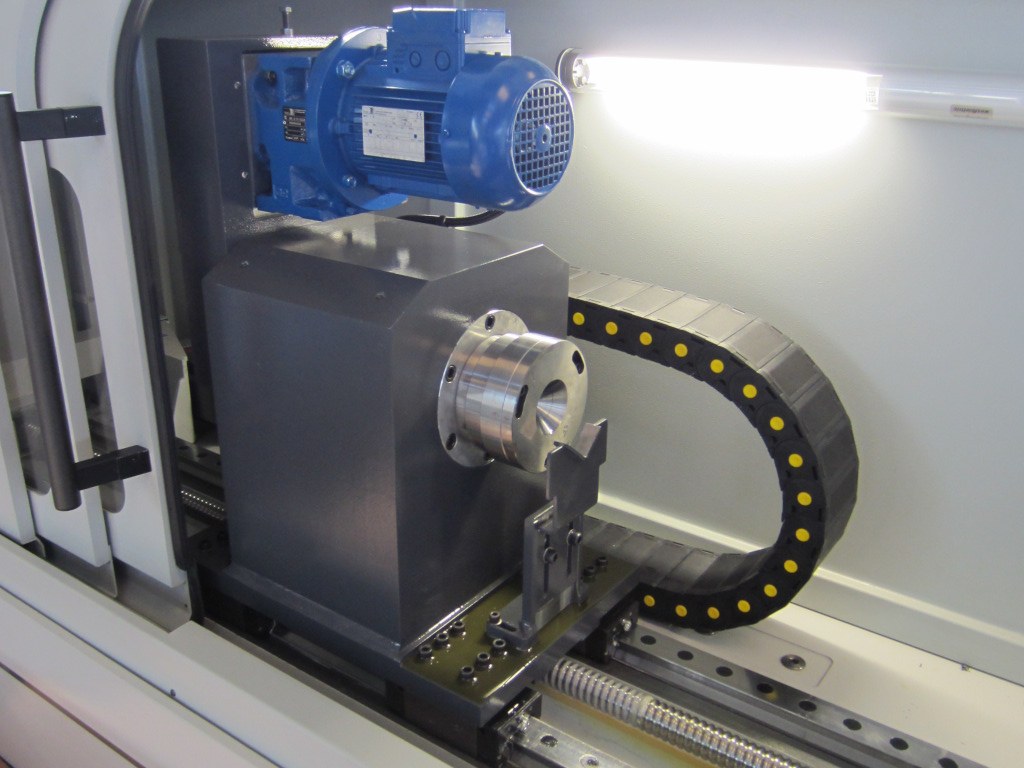

Cnc Deep Hole Drilling Machine for cylindrical parts, on-center holes

- The IMSA deep hole drilling machines MFT 500 CR, 1000 CR, 1500 CR (the number indicates the max. drilling depth) are dedicated to cylindrical workpieces that have to be drilled on their rotation axis. Hole diameter range 6 – 25 mm. Some applications: transmission shafts, gear shafts, lubricators, valves, in general all round workpieces that have to be drilled on-center.

- Deep drilling method: gun drill tool. Drilling spindle: 7,5 kW, 6.000 rpm.

- The workpiece is in counter-rotation in respect to the gun drill, in order to obtain the maximal drill straightness and process speed. Counter-rotation 150 rpm.

- Specific IMSA functions to control the deep drilling process:

– Electronic check of cutting parameters,

– Double electronic check against gundrill-breaking, by reading the cutting effort. - Temperature, pressure and oil cleanliness are fundamental parameters to ensure continuous trouble-free gun drilling operations. The deep hole drilling machines of IMSA MFT Series are equipped with the best solutions that automatically manage these three parameters to the most suitable value:

– high-pressure pump, continuously managing pressure and flow;

– for oil clarification: a complete two-level filtering system;

– for oil cooling: a heat exchanger (chiller).

Options

- Workpiece automatic loader,

- Controlled CR head movement,

- Automatic door opening,

- Automatic chip conveyor,

- Steadyrest for workpiece support.