SINGLE-SPINDLE

GUN DRILL TOOL

Cnc Deep Hole Drilling Machine for cylindrical parts, on-center holes

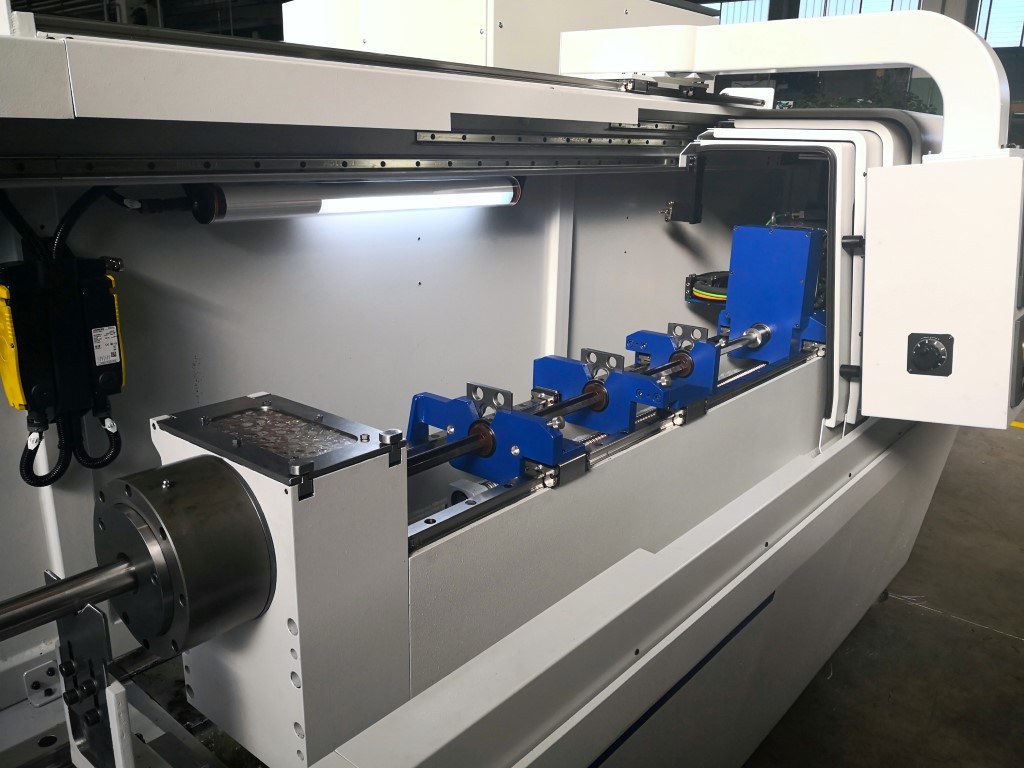

- The IMSA deep hole drilling machines MFT 1000 /32 CR and MFT 1500 /32 CR are dedicated to cylindrical workpieces that have to be drilled on their rotation axis. Hole diameter range 6 – 32 mm. Some application examples: gear shafts, aerospace industry, flanges for industrial applications, deep drilling job shops.

- Drilling depth: max. 1.000 mm for the model MFT 1000 /32 CR; max. 1.500 mm for the MFT 1500 /32 CR.

- Deep drilling method: gun drill tool. Drilling spindle: 9 kW, 6.000 rpm.

- The workpiece is in counter-rotation in respect to the gun drill, in order to obtain the maximal drill straightness and process speed. Counter-rotation 150 rpm.

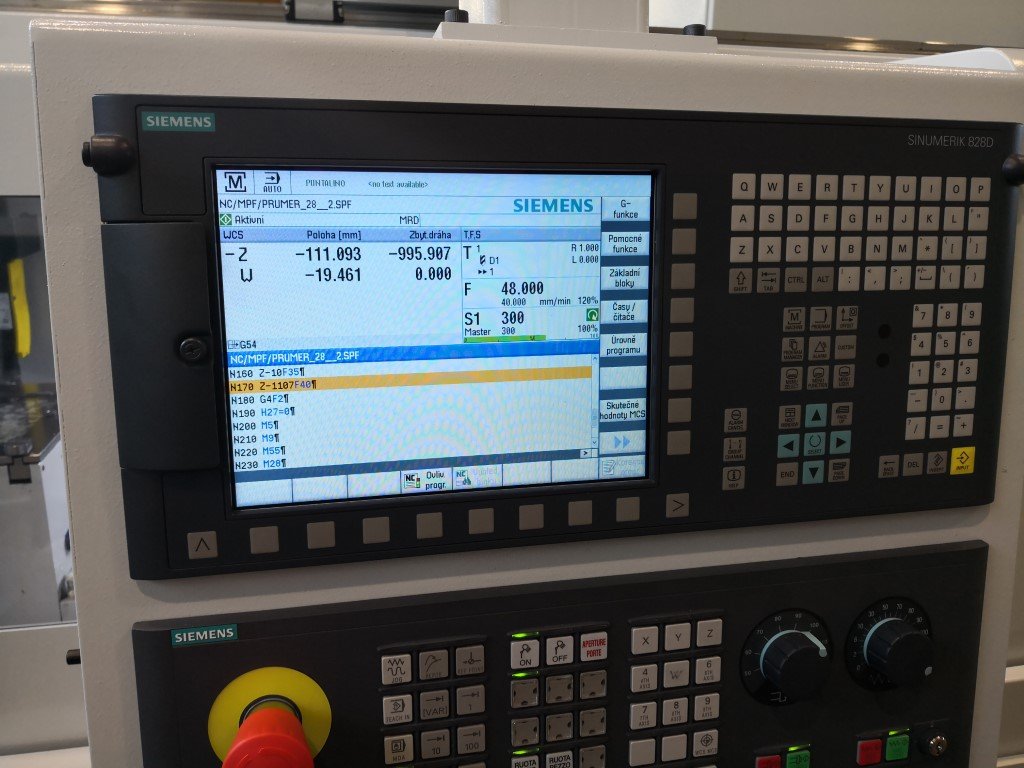

- Specific IMSA functions to control the deep drilling process:

– Electronic check of cutting parameters,

– Double electronic check against gun drill-breaking, by reading the cutting effort. - Temperature, pressure and oil cleanliness are fundamental parameters to ensure continuous trouble-free gundrilling operations. The deep hole drilling machines of IMSA MFT Series are equipped with the best solutions that automatically manage these three parameters to the most suitable value:

– high-pressure pump, continuously managing pressure and flow;

– for oil clarification: a complete 3-level filtering system;

– for oil cooling: a heat exchanger (chiller).

Options

- Workpiece automatic loader,

- Automatic door opening,

- Automatic chip conveyor,

- Steadyrest for workpiece support.