Deep Hole Drilling Machine

The simplest 3-4 axes solution for blocks, mold inserts and plates.

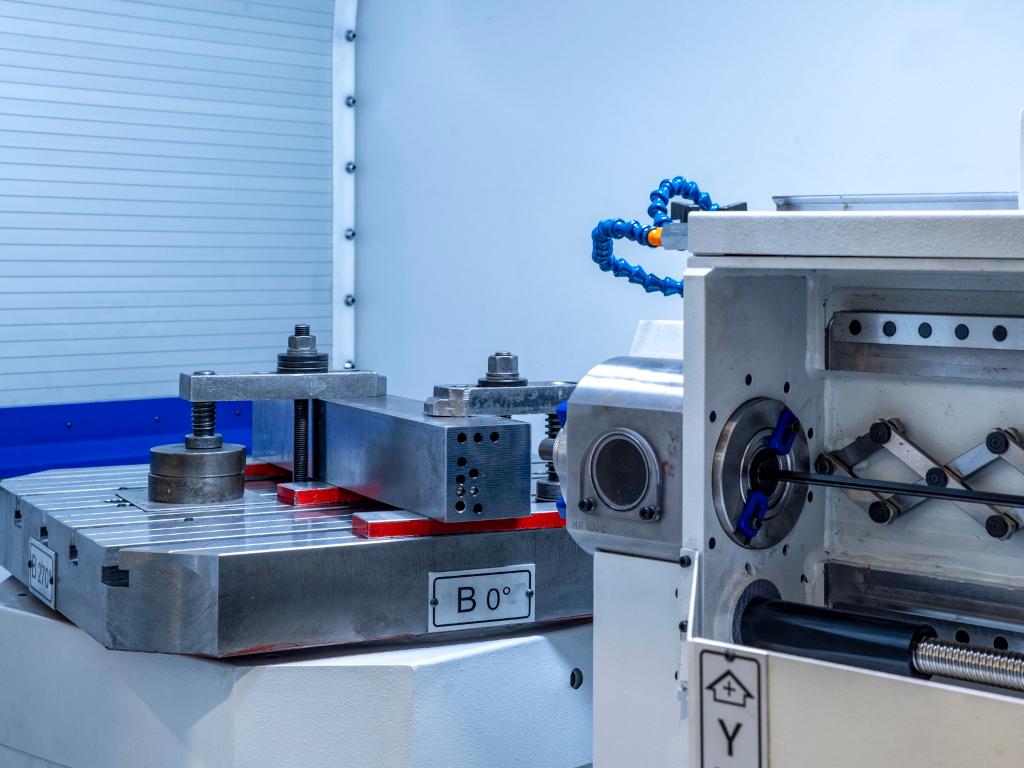

The IMSA deep hole drilling machine MF800C can also be used to drill centered and off-center deep holes in cylindrical parts.

Drilling depth in single operation max. 800 mm. Tool: gun drill.

The deep drilling operation on a specific machine as MF800C is much more economical than drilling on a non-specific machine.

Straight drilling for the machine in basic version;

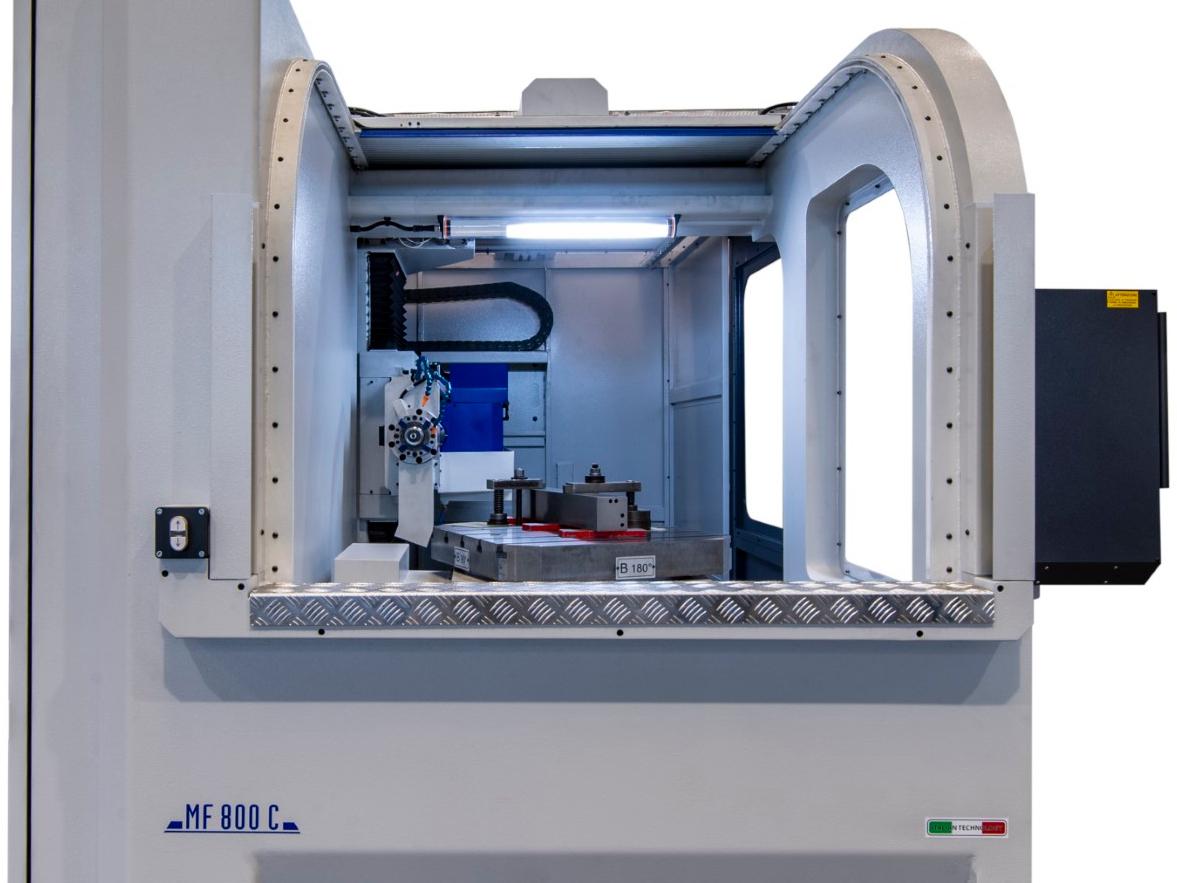

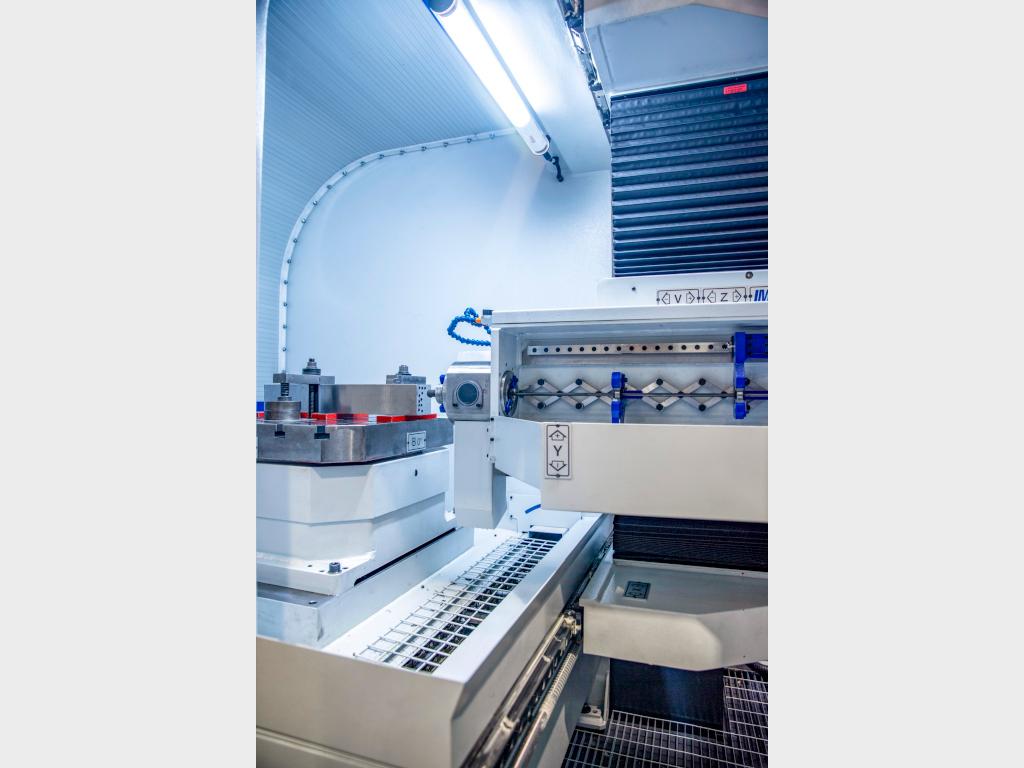

Straight and angled drilling (4-axes) for the machine equipped with the optional rotary table.

Temperature, pressure and oil cleanliness are fundamental parameters that ensure continuous trouble-free gun drilling operations. That’s why our MF800C is equipped with the best solutions that can automatically manage those three factors to the most suitable value. MF800C is a compact yet complete machine.

Reliable and safe process: the structure rigidity of our gantry solution -rated as 16 times more rigid than in the bottom-guided traditional structure- combined with special IMSA functions for the checking of effort values during drilling, result in top-level reliability and enable long unattended machining.

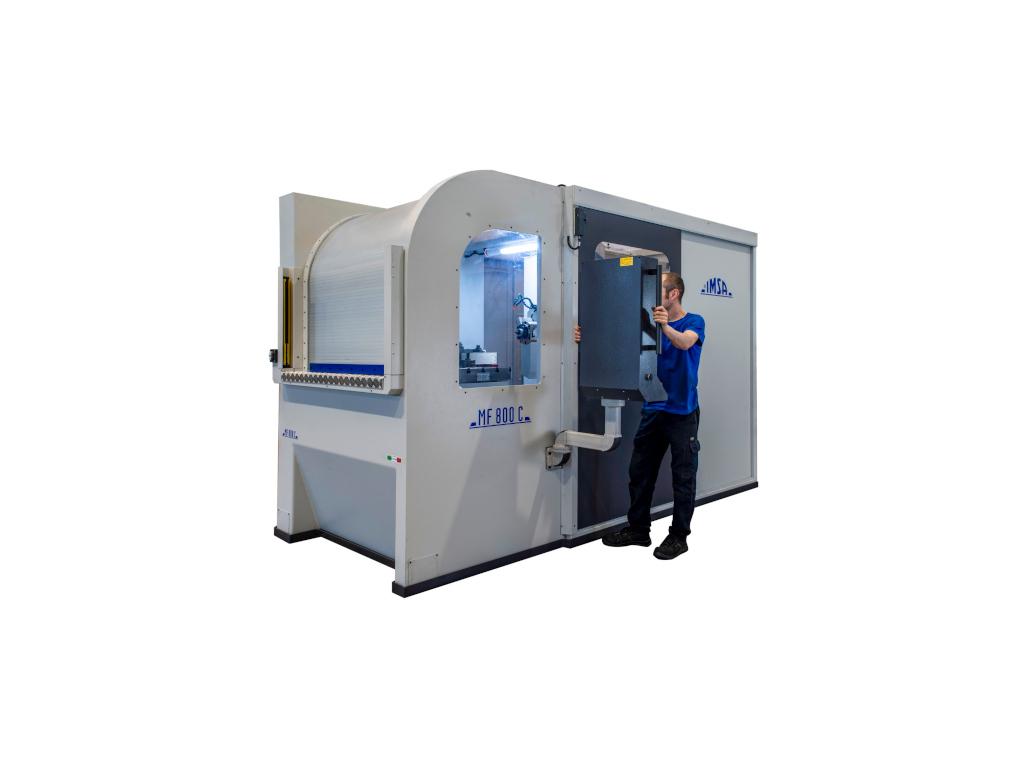

This deep hole drilling machine is conceived with a “shell-like” structure. That is, the machine self-supporting structure integrates table and gantry column, and requires no foundations.

Easy loading with hall crane (from top) as well as by forklift (from machine front) thanks to the front door leaving spacious access to the machine table. Good visibility of table and workpiece, thanks to the wide transparent windows on the operator side.

MF800C is completely enclosed and placed on floor pans, guaranteeing area cleanliness as well as oil tightness.