MILLING AND GUN DRILLING CENTER

FOR MOLDS UP TO 30 TONNES

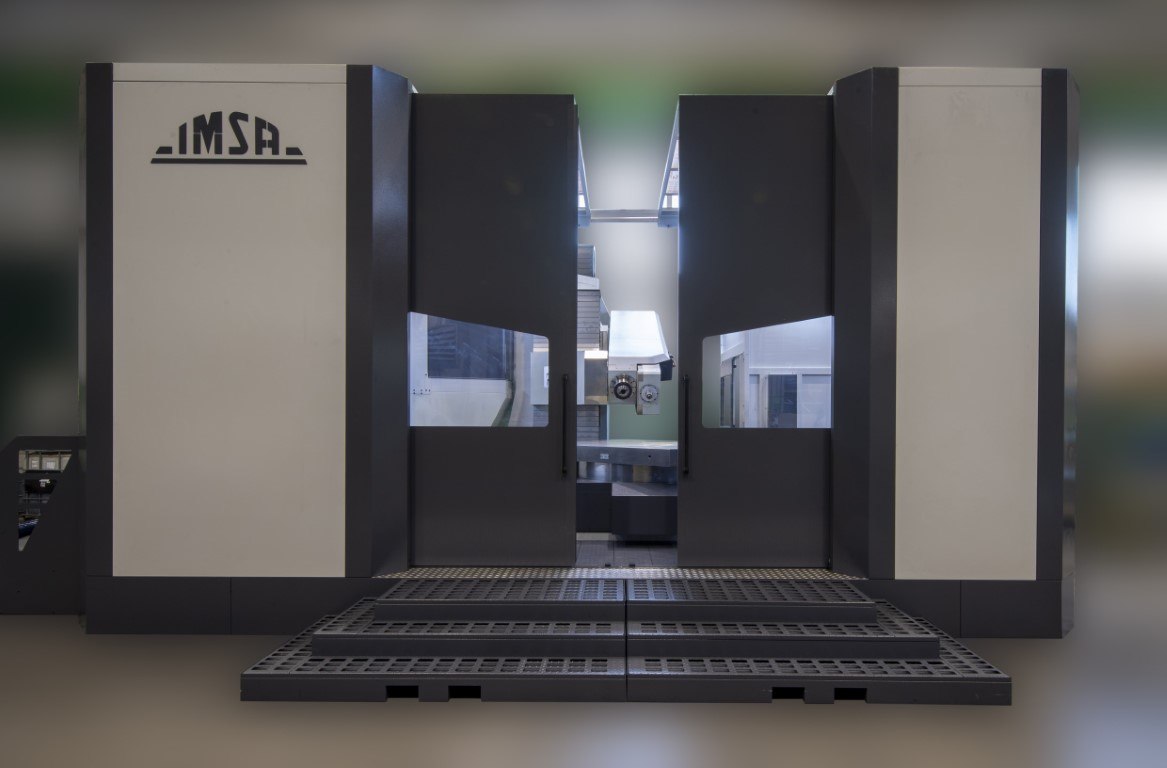

- The Milling and Gun Drilling Center IMSA MF1600S2 has been designed to respond to the needs of manufacturers of tool and dies up to 30 tons in the mold making industry. MF1600S2 has a heavy built electrowelded structure and a T-shape machine concept: translating table and transversal movable column.

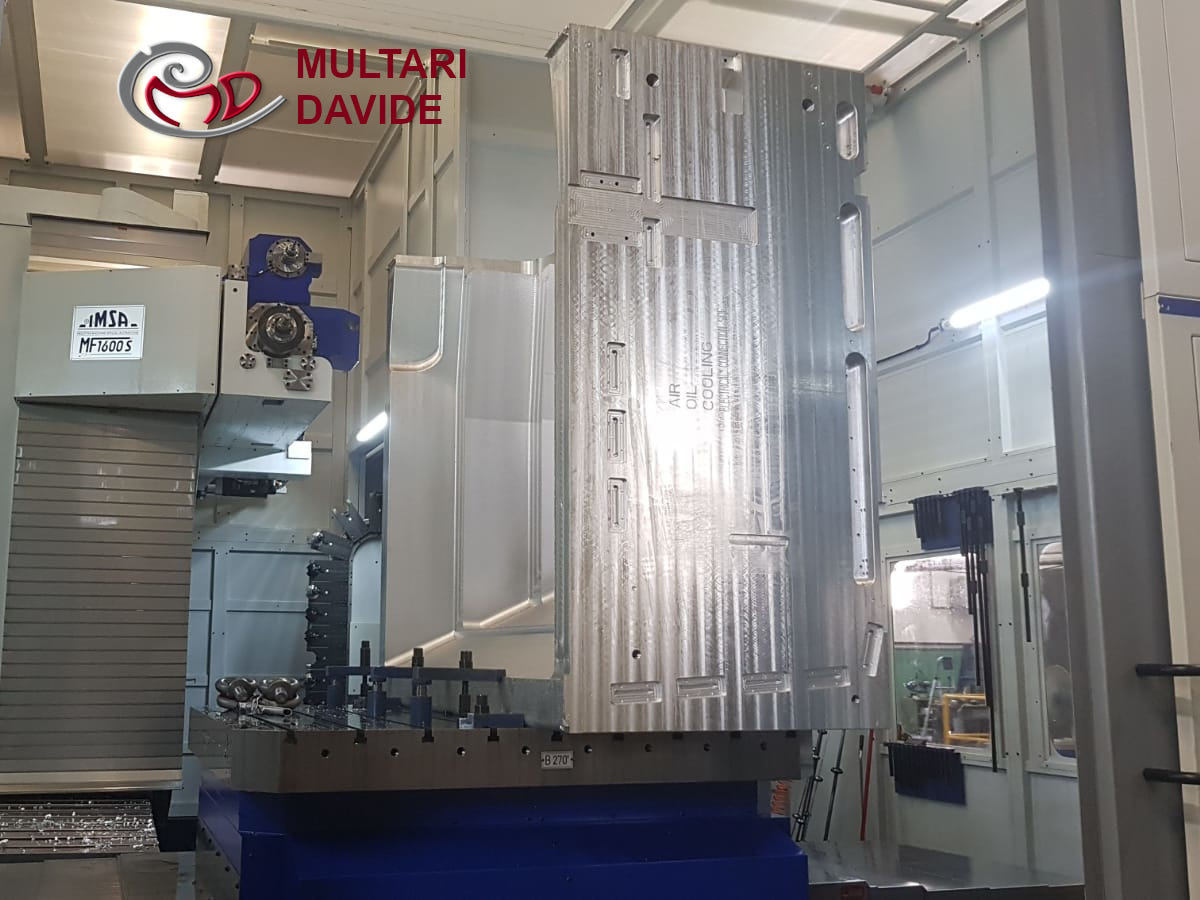

- A mold having a diameter as large as 3600mm can rotate inside the machine structure. The table has a traversing movement (X axis) of 3000mm and an infinite-position rotation movement (B axis).

- Orthogonal machining, with single angle and compound-angle (5-axes machining) thanks to 360° table rotation and 30°-15° headstock inclination.

- 4-Side Machining: the MF1600S2 has a long transversal movement and its table combines high loading capacity and compact size. These features strongly facilitate 4-side machining with one workpiece setup.

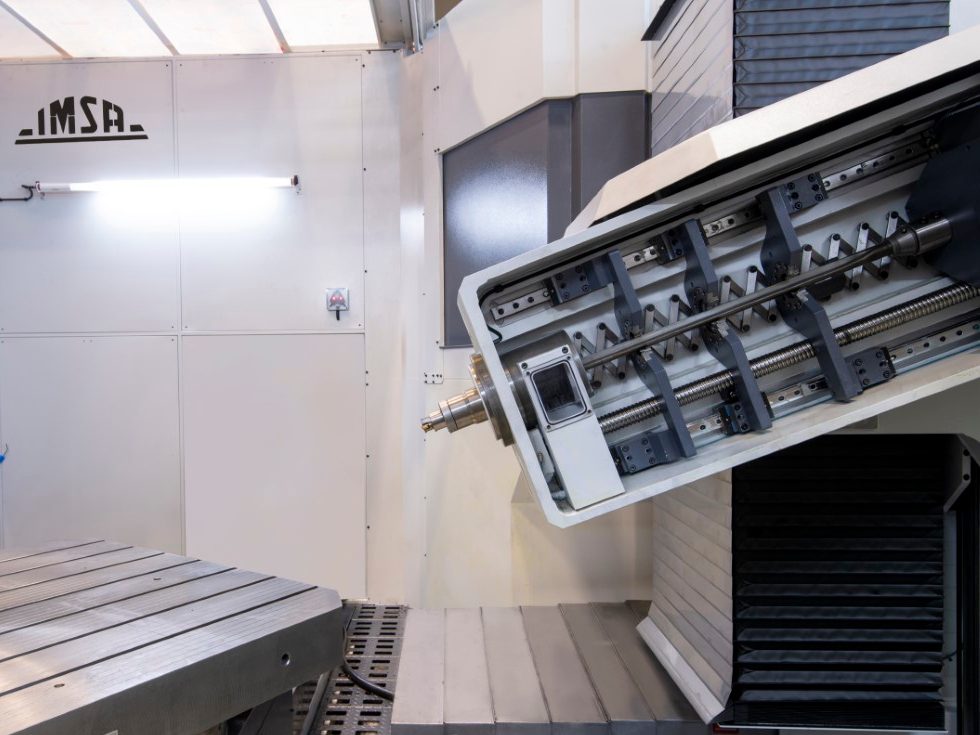

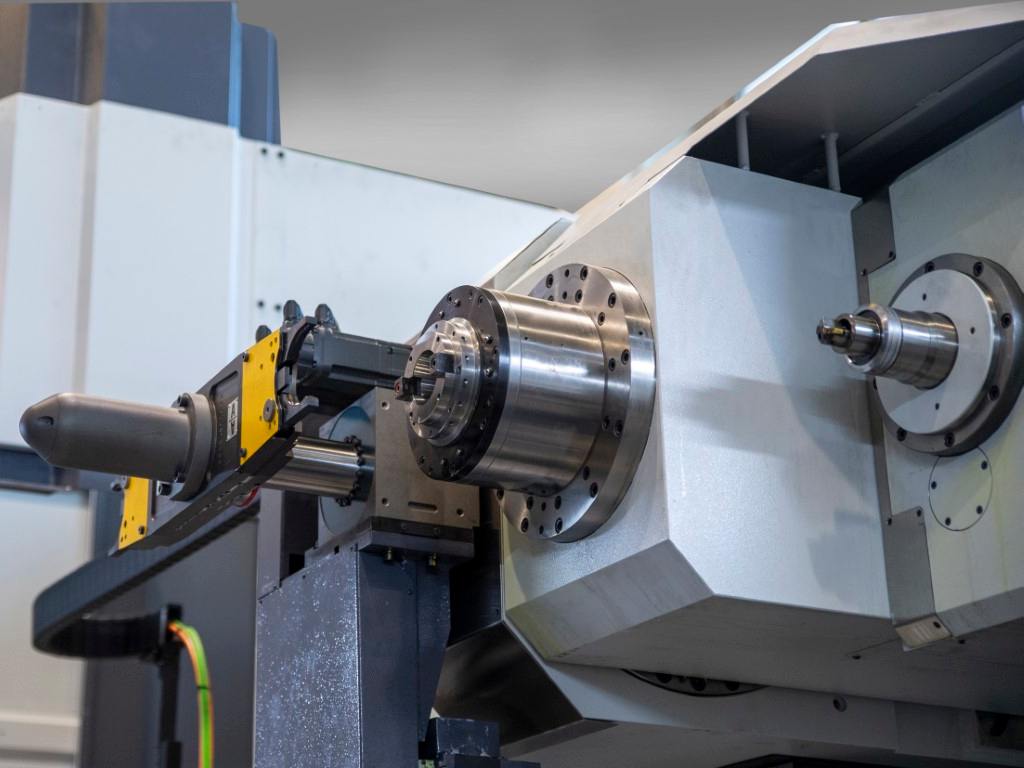

- Two separate machining units, located on the same headstock, carry out milling and gun drilling operations. This independent-axis system, distinctive feature of IMSA machines, provides the means for switching from drilling to milling and vice versa in just 8 seconds and does not require human intervention.

- MILLING UNIT: MF1600S2 has a ISO50 machining spindle, 35 kW, 6.000rpm, 334 Nm (S1), liquid cooled motor.

- Different capacity ISO50 tool storages available in option.

- DEEP HOLE DRILLING: Drilling depth in single operation: up to 1600 mm. Drilling method: gun drilling. Optimal drilling diameter range: 5-32 (40) mm. Gun drill spindle: 15 kW (S1), 4200 rpm.

- Specific IMSA functions control the deep drilling process.

- The gundrill unit features as many as 6 key alignment points, solidly aligned on the headstock structure. The result is a rigidity that enables you to drill in average 6-8 times longer in comparison to gun drill machines where the chip box and steadyrests are removable.

- Temperature, pressure and oil cleanliness are fundamental parameters to ensure continuous trouble-free gun drilling process. For this reason, the MF1600S2 is equipped with the best solutions that can automatically manage these parameters to the most suitable value.