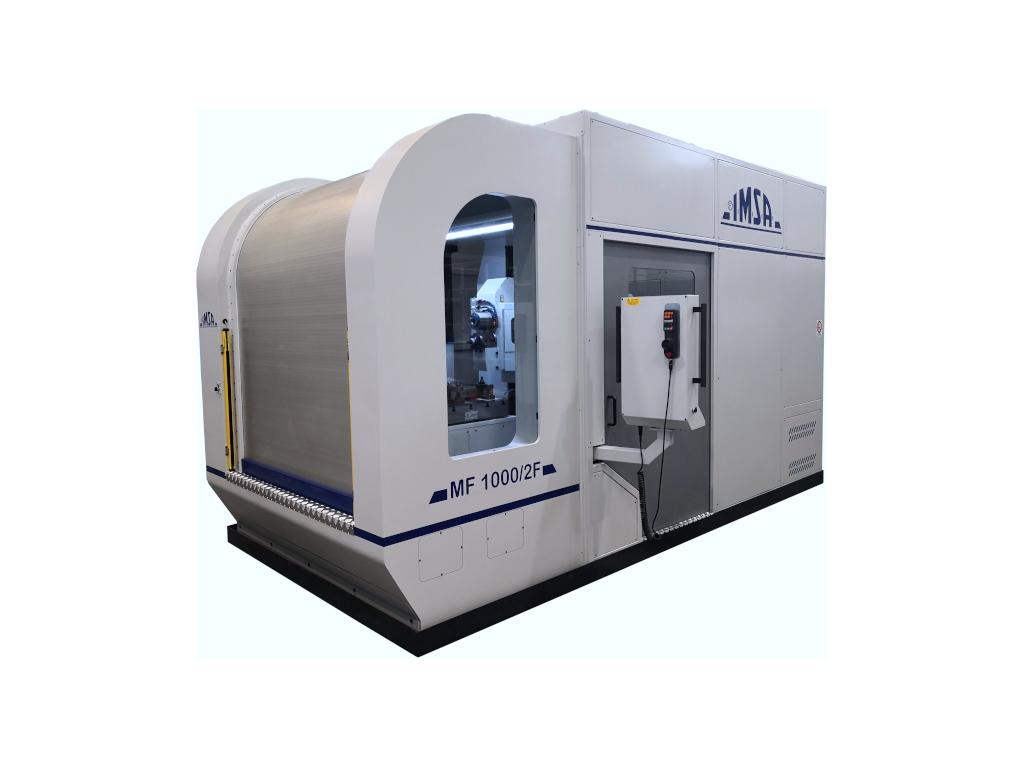

IMSA GUN DRILLING AND MILLING MACHINE

FOR MIDDLE-SIZE MOLDS AND BLOCKS

- The IMSA gun drilling and milling machine MF1000/2F is suitable for molds/blocks up to 4 / 6,5 tonnes. A workpiece having a diameter as large as 1600mm can rotate inside the machine structure.

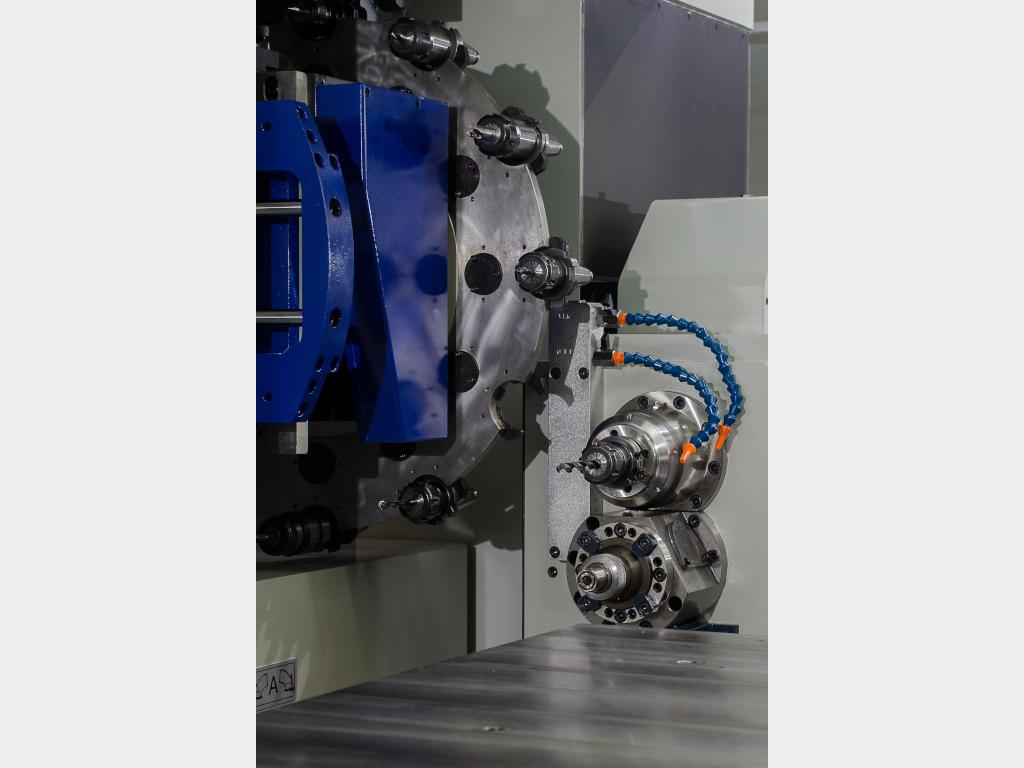

- Rotary table, infinite position 360000pos/rev., size 800x1000mm, max. load 4000kg. Or (option) rotary table, infinite position 360000pos/rev., size 1000x1200mm, load 6.500kg.

- (you may also be interested in MF1000/2F with rotary-tilting table)

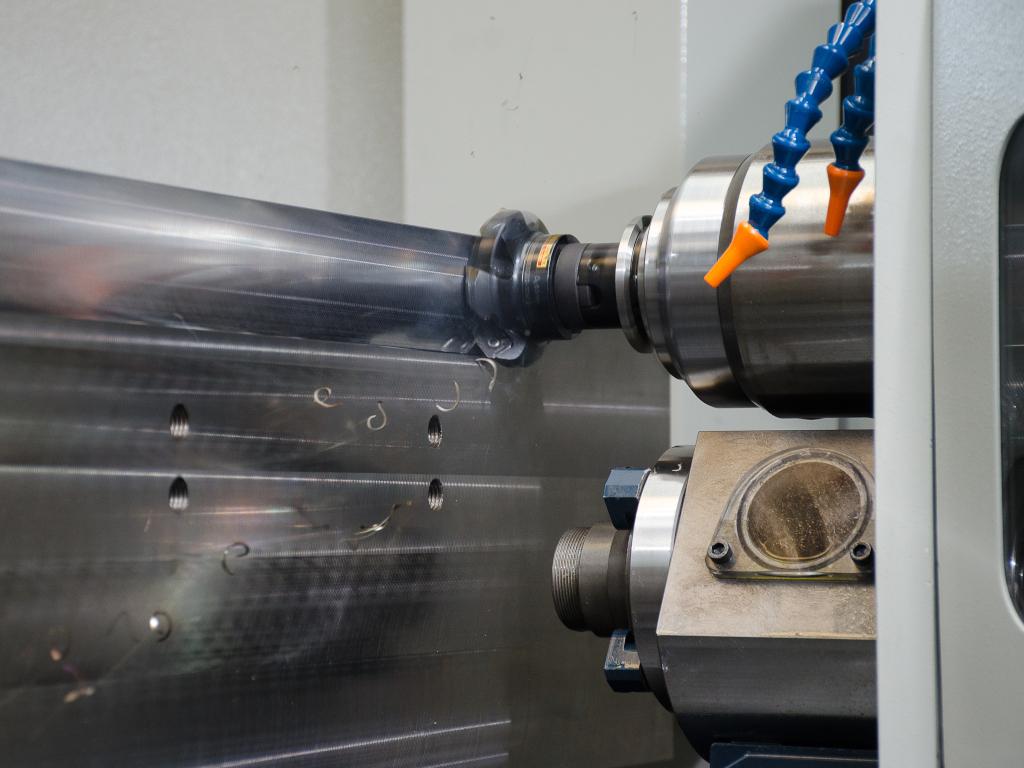

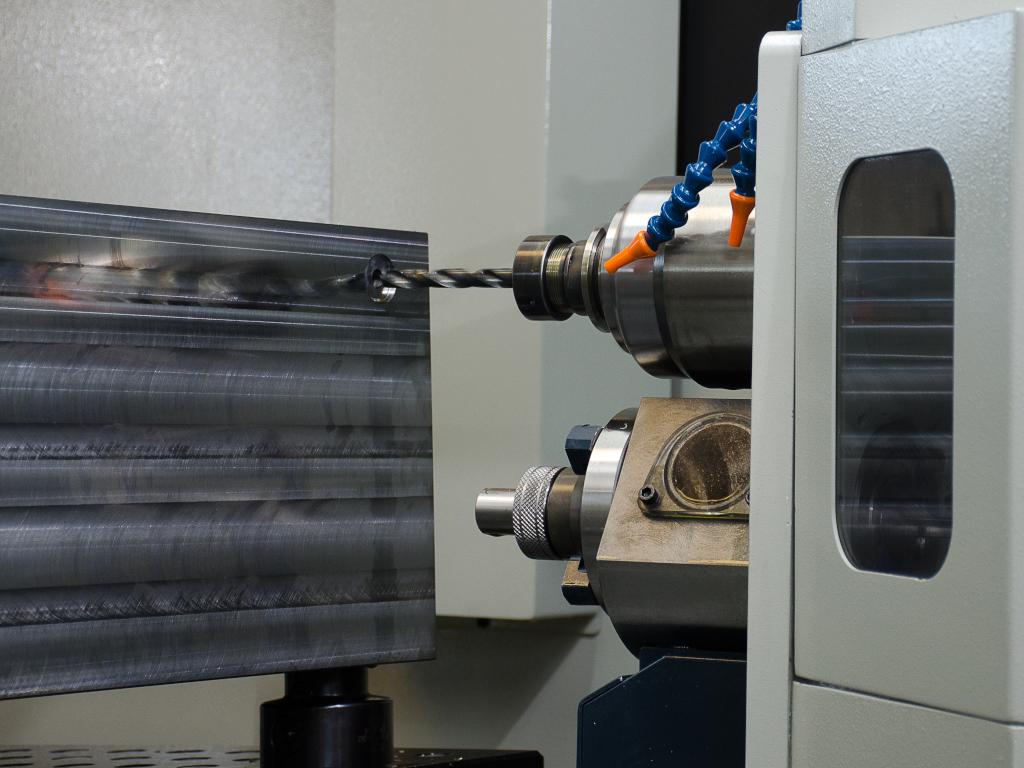

- Drilling depth in single operation: 1000 mm. Drilling method: gun drill. Deep drilling spindle, power 11 kW, 6000 rpm, for gun drilling Ø 4-25 mm, max. 32 mm counterboring or in short-chipping materials. This spindle is generally utilized to drill water lines in molds.

- Specific IMSA functions for deep drilling process control:

– Electronic workpiece approach

– Electronic check against gun drill breaking, by reading the cutting effort

– Special coordinate transformation function for angled machining.

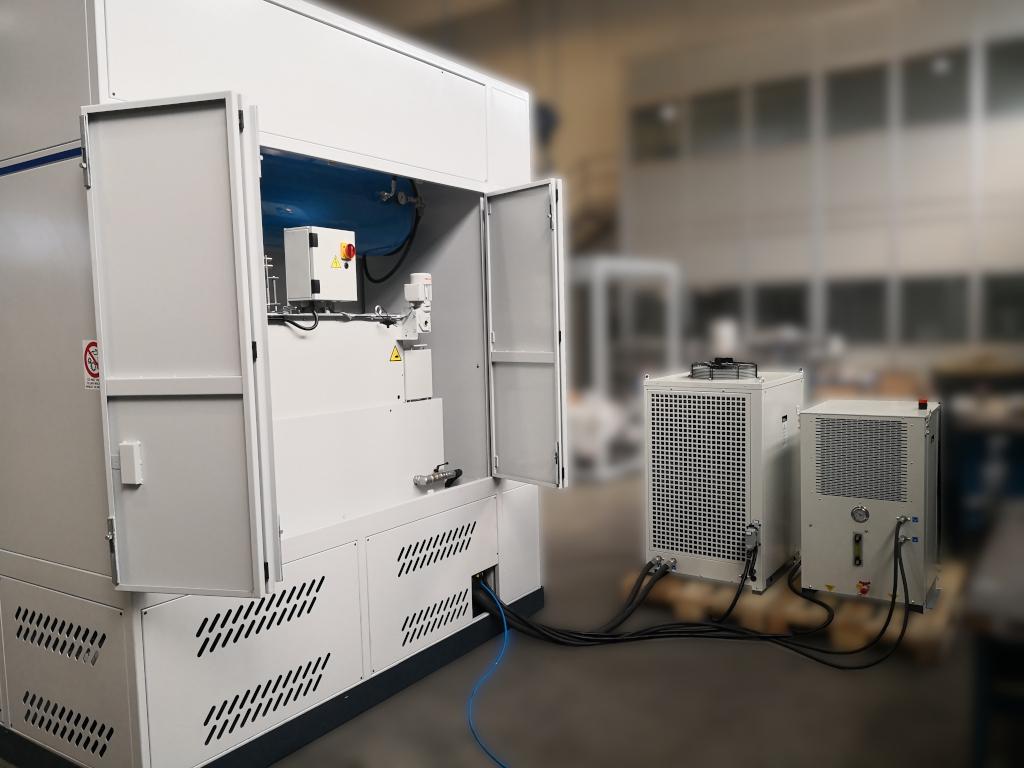

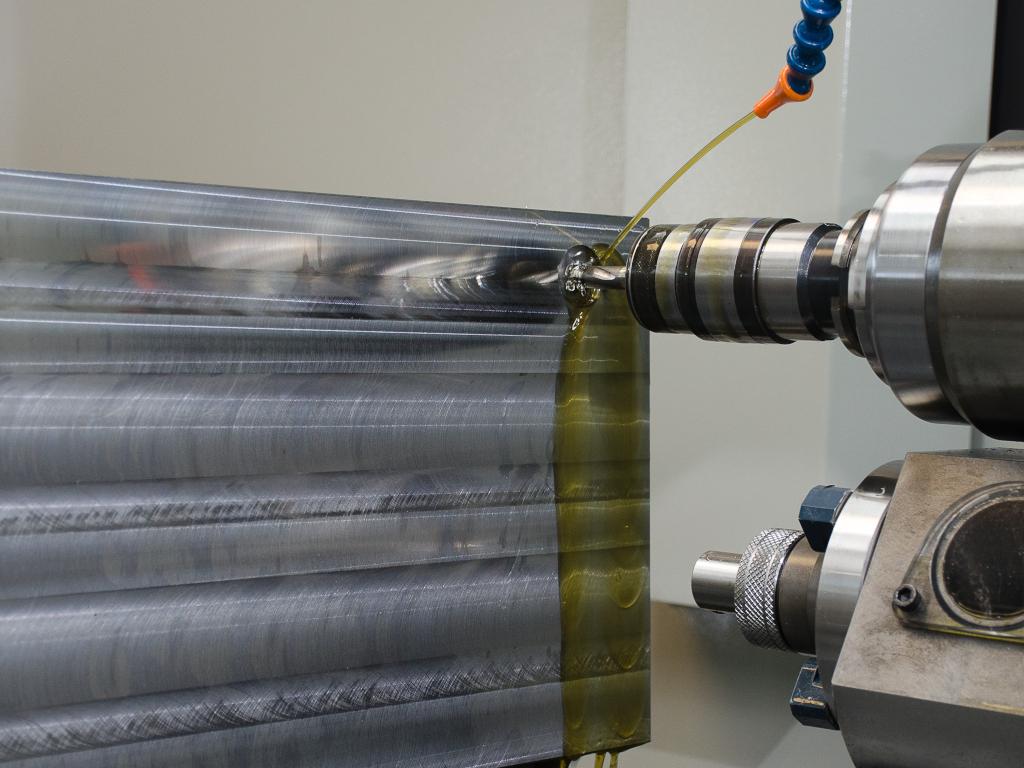

- Temperature, pressure and oil cleanliness are fundamental parameters to ensure continuous trouble-free gun drilling operations.

For this reason the MF1000/2F is equipped with the best solutions that can automatically manage those three parameters to the most suitable value:

– for oil supply to the gun drill: two different high-pressure pumps;

– for oil clarification: a complete filtering system;

– for oil cooling: a heat exchanger (chiller). The chiller is on a parallel oil circuit, and can be flexibly positioned around the machine.

- Chip conveyor as standard equipment.

- Auxiliary milling head ISO40, power 13 kW, 6000 rpm. The milling head is positioned on the headstock, on top of the drilling slide, and is optimized for machining operations that prepare and complete the deep holes (spot facing, spade drilling, rigid tapping or thread milling). No intervention required for switchover gundrilling/milling and back. High-pressure oil (50 bar) through milling spindle. Automatic tool changer for milling head.

- MF1000/2F has a vertical gantry structure, resulting in better rigidity: bending moment 4 times lower than in low-supported column structure, 16 times higher rigidity. The gantry column ensures the best performances all along the Y axis travel.

- This machine is conceived with a “shell-like” structure. That is, the MF1000/2F self-supporting structure integrates table and gantry column, and requires no foundations.

- A modern coverage encloses the whole machine, so that oil is contained inside the machine and cleanliness of the workshop area is ensured. The frontal door ensures spacious access for workpiece loading with hall crane or fork lift. The latest shutter-style aluminum oil-proof front door is more resistant and long-lasting in respect of the previous design with Lexan sheet.