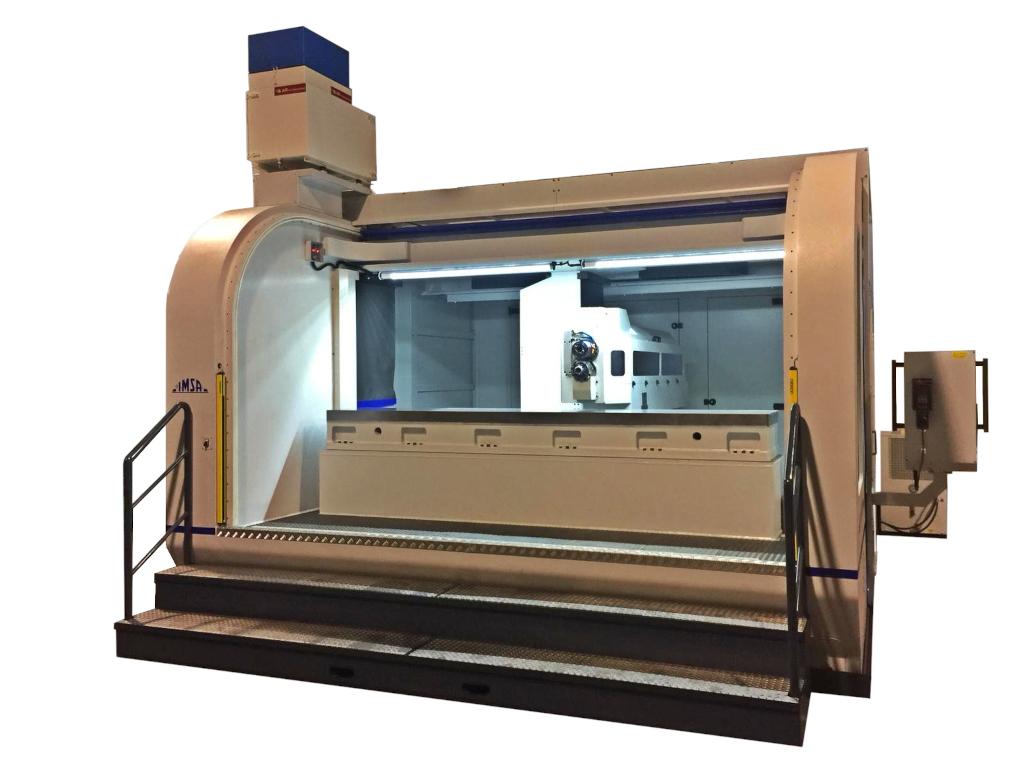

READY-FACTORY | MF1000/2C | IMSA gun drilling and milling machine

1 NEW gun drilling and milling machine MF1000/2C is now available READY-FACTORY, subject to prior sale. Machine for blocks, mold inserts and mechanical components up to 2 tons. MF1000/2C can also be used to drill centerline and off-center deep holes in cylindrical parts. Deep drilling method: by gun drill tool. Drilling depth up to 1000 mm. Drill diameter range 4-25 mm solid, up to 32 mm in counterboring. Headstock with separate gun drilling and milling spindle, fully automatic commutation. Rotary-tilting table enables compound-angle machining.

MF1200 D

IMSA simple 3-4 axes solution for blocks, mold inserts and plates.

The IMSA deep hole drilling machine MF1200D can also be used to drill centered and off-center deep holes in cylindrical parts.

Drilling depth in single operation max. 1200 mm. Table load 4000 kg.

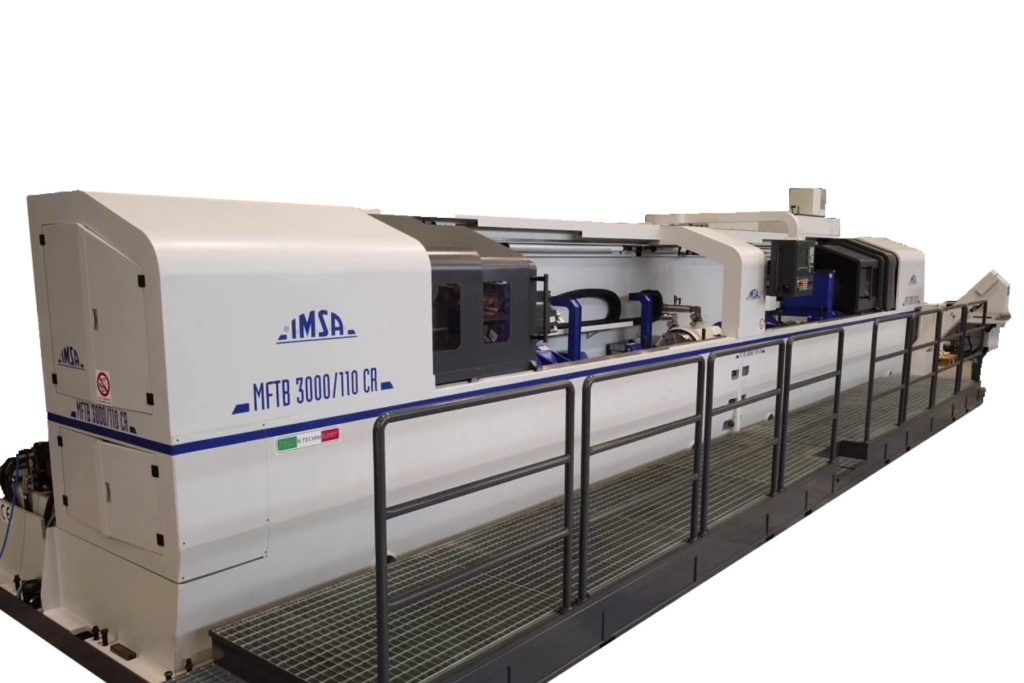

MFTB 1000/76 GDK – MFTB 2000 /76 GDK – MFTB 3000 /76 GDK

Centerline deep hole drilling machine for cylindrical parts. In the intermediate diameter range between the Gun Drilling and the BTA Drilling, we propose a Double-Setup flexible solution we called IMSA “GDK” System. This enables you to better take advantage of both tool types. Drilling diameter range with gun drill tools: 8 -25 mm solid; drilling diameter range with BTA tools: 20 – 76 mm solid.

SPECIAL OFFER | MF1500B2 | IMSA DEEP HOLE DRILLING MACHINE

Pre-owned IMSA machine fully revamped and re-registered by the manufacturer. Cnc Gun Drilling Machine for hole Ø 5-25 mm solid, max. drilling depth 1.500 mm (V-axis). Table load 10.000 kg. Auxiliary ISO40 spindle.

MFT 750/2T CR – MFT 1500/2T CR

Centerline deep hole drilling machines. These “2T” machines are equipped with a single carriage with two spindles, enabling you to drill 2 identical parts in each drilling cycle. Method: gun drilling. Workpiece in counter-rotation. Drilling diameters: 6 – 24 mm. Drilling depth (respectively) 750 mm, 1500 mm.

MFT 1000 /2Ti CR – MFT 1500 /2Ti CR

Centerline deep hole drilling machines. These “2Ti” machines are equipped with 2 independent drilling carriages that enable you to drill 2 different workpieces in each cycle. Method: gun drilling. Workpiece in counter-rotation. Drilling diameters: 6 – 25 mm. Drilling depth (respectively) 1000 mm, 1500 mm.

MFT 1000EVO

Centerline deep hole drilling machine. Single spindle. Drilling method: gun drill tool. Workpiece in counter-rotation. Drilling diameters: 4 – 25 mm. Drilling depth (160 x Ø) max. 1000 mm. This EVO version manages pressure and flow by an inverter; moreover, it enables a very quick setup thanks to full-cnc movements.

MFTB 3300 /110EVO

Centerline deep hole drilling machine specific for aeronautical shafts, martensitic stainless steels in particular. Single spindle. Drilling method: by BTA tools. Workpiece in counter-rotation. Drilling diameters: 30 – 110 mm. Drilling depth: max. 3300 mm.

MFTB1000/51 GDK – MFTB1500/51 GDK – MFTB2000/51 GDK

Centerline deep hole drilling machine for cylindrical parts. In the intermediate diameter range between the Gun Drilling and the BTA Drilling, we propose a Double-Setup flexible solution we called IMSA “GDK” System. This enables you to better take advantage of both tool types. Drilling diameter range with gun drill tools: 8 -24 mm; drilling diameter range with BTA tools: 18 – 51 mm.

MFTB1000/51 CR – MFTB1500/51 CR – MFTB2000/51 CR

Centerline deep hole drilling machine for cylindrical parts. Method: BTA drills. Workpiece in counter-rotation. Drilling depth (respectively) 1000 mm, 1500 mm, 2000 mm. Drilling diameter: 18-51 mm.

MFTB1000/76 CR – MFTB2000/76 CR – MFTB3000/76 CR

Centerline deep hole drilling machine for cylindrical parts. Deep drilling method: BTA/STS. Drilling depth (respectively) 1000 mm, 2000 mm, 3000 mm. Drilling diameter range: 20 – 76 mm.

MFTB1000/110 – MFTB2000/110

Centerline deep hole drilling machine for steel shafts and other cylindrical parts that have to be drilled on their rotation axis. Deep drilling method: BTA/STS. Drilling depth (respectively) 1000 mm, 2000 mm. Drilling diameter range: 20 – 110 mm (in option, up to 135 mm in counter-boring).

MFTB2000 /200

Centerline deep hole drilling machine for steel shafts and other cylindrical parts that have to be drilled on their rotation axis. Deep drilling method: BTA/STS. Drilling depth: 2000 mm. Drilling diameter range: 50 -200 mm.

SPECIAL OFFER | MF1000B2 | IMSA DEEP HOLE DRILLING MACHINE

Pre-owned IMSA machine fully revamped and re-registered by the manufacturer. Cnc Gun Drilling Machine for hole Ø 4-20 mm solid, max. drilling depth 1000 mm (V-axis). Table load 4000 kg. Auxiliary ISO40 spindle

MFT 1000 /32 CR – MFT 1500 /32 CR

Centerline deep hole drilling machines for steel shaft and other cylindrical parts that have to be drilled on their rotation axis until Ø32, such as: gear shafts, aerospace industry, flanges for industrial applications. Single spindle. Method: gun drilling. Drilling diameters: 6 – 32 mm. Drilling depth (respectively) 1000 mm, 1500 mm.

MFT 1000 /43CR – MFT 1500 /43CR

Centerline deep hole drilling machines for steel shaft and other cylindrical parts that have to be drilled on their rotation axis until Ø43, such as: gear shafts, aerospace industry, flanges for industrial applications. Single spindle. Method: gun drilling. Drilling diameters: 8 – 43 mm. Drilling depth (respectively) 1000 mm, 1500 mm.

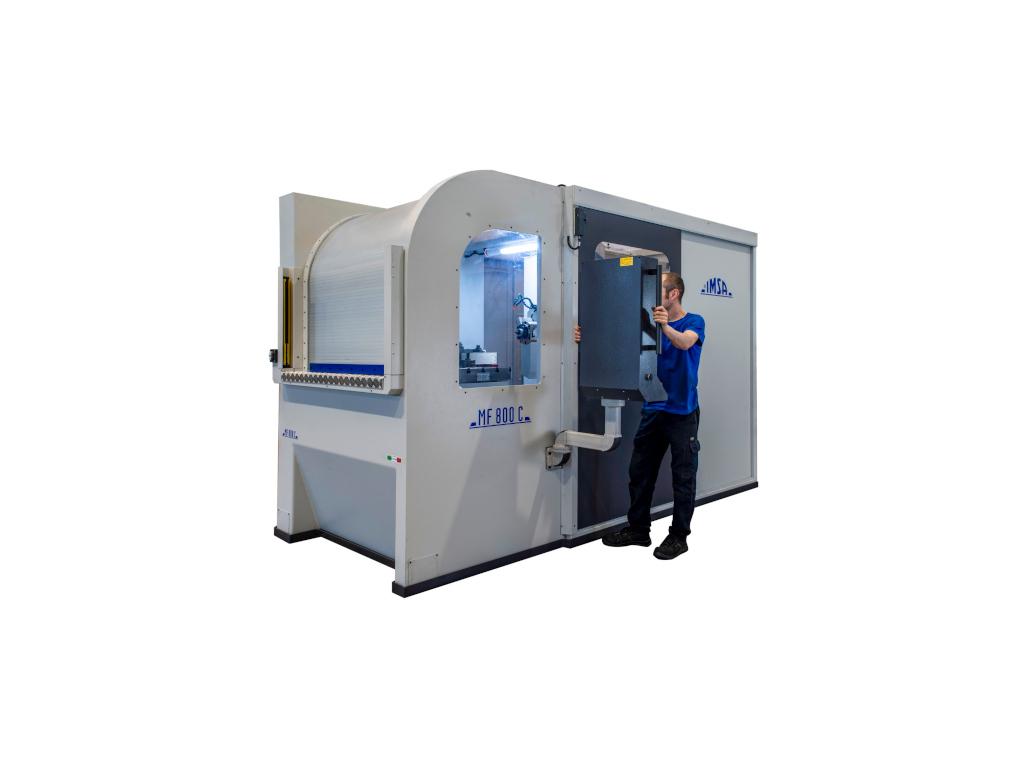

MF800C

IMSA’s simplest deep drilling machine for blocks and plates, and for off-center deep holes in cylindrical parts. Drilling depth max. 800 mm. Table load: 2000 kg (on optional rotary table); 4000 kg (on standard fixed table).

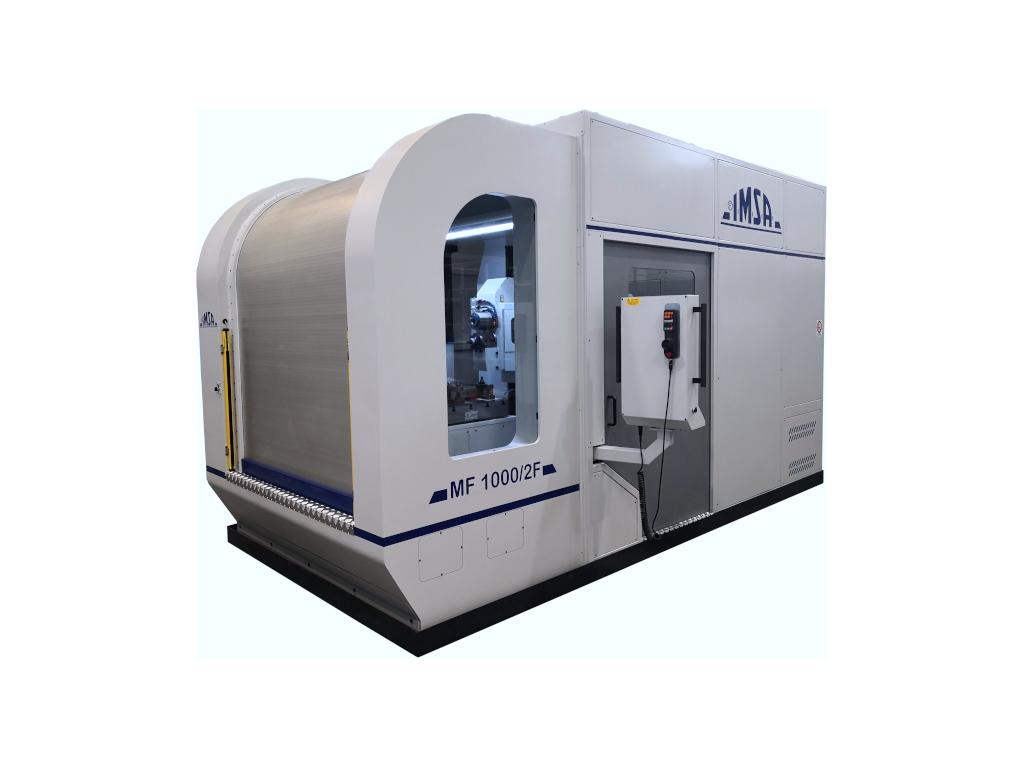

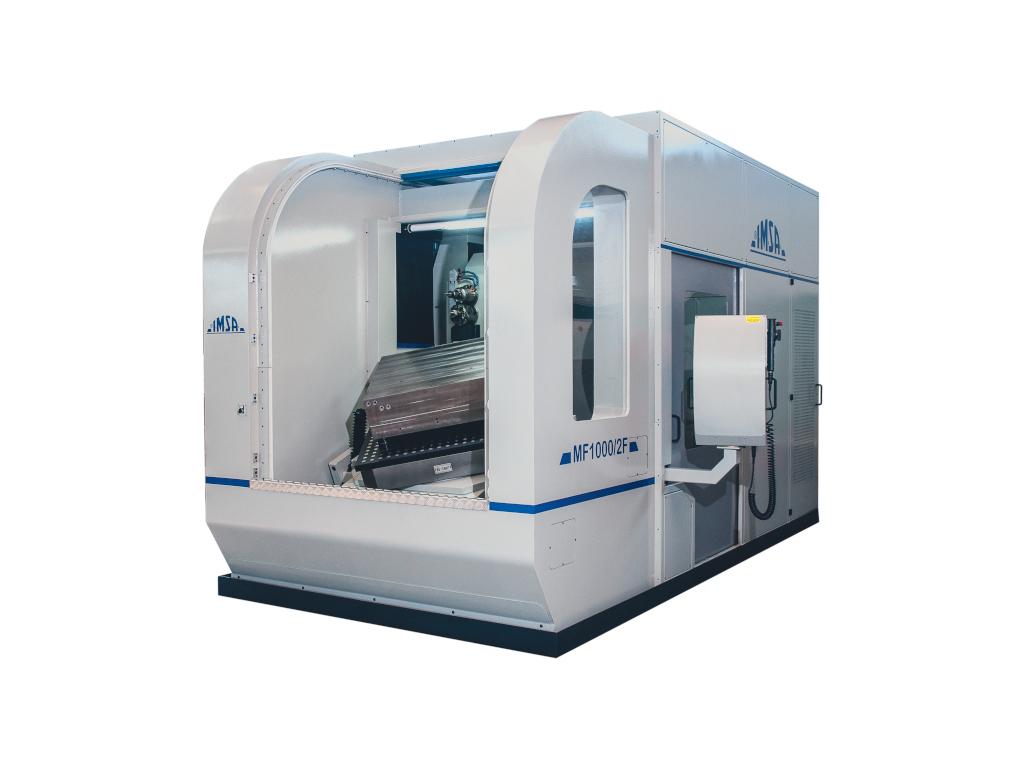

MF1000/2F with Rotary Table

Gun drilling and milling machine for middle-size molds.

Headstock with separate gun drilling and milling spindle, fully automatic commutation.

Straight and single-angle drilling: this machine version is equipped with a rotary table. Table load up to 4000 kg or 6500 kg.

MF 500/6T

Deep hole drilling machine with 6 independent gundrilling heads for glass bottle moulds

MF700/3000

Single-spindle gundrilling machine with increased horizontal travel.

MF 350/4TA

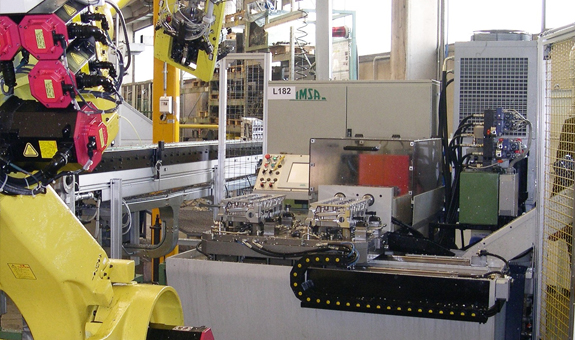

Deep hole drilling special machine with 4 independent heads integrated in automatic production line type FMS.

MF 600/2T

Deep hole drilling machine with two independent heads, integrated in production cell with autoloading. Automotive industry.

MFT6000/CR

Centerline deep hole drilling machine for cylindrical parts. Gundrilling tool, workpiece in counter-rotation, on-center drilling. Drilling depth 6 meters.

MF 500 4+4T

Deep hole drilling solution for automotive industry. Machine with 4+4 opposed heads integrated in production cell.

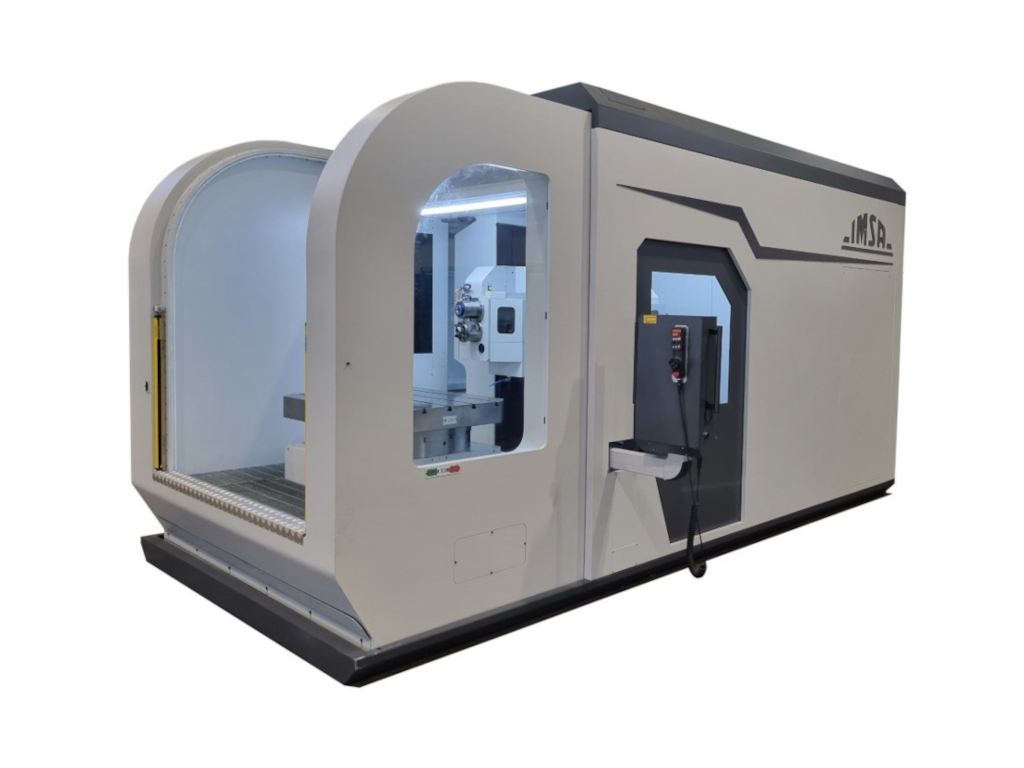

MF1000 /2C

Gun drilling and milling machine molds and mechanical parts up to 2 or 4 tonnes, depending on the chosen table.

Machine version with rotary table, or machine version with rotary/tilting table.

Headstock with separate gun drilling and milling spindle, fully automatic commutation.

MF1000/2F with Rotary-Tilting Table

Gun drilling and milling machine for middle-size molds with complex waterlines.

Headstock with separate gun drilling and milling spindle, fully automatic commutation.

Straight, single-angle and compound-angle drilling: this machine version is equipped with a rotary/tilting table. Table load 5000 kg.

MF1750 EVO

“GUNDRILLING AND MILLING IN SINERGY”: EVO-Series Gundrilling and Milling Center for molds that require multiple-axis waterlines. Vertical Gantry structure. The Gun Drill Center MF1750EVO is suitable for large molds up to 30 / 40 / 45 tonnes, depending on the selected table. A workpiece of diameter 4,300mm max can rotate inside the machine structure.

Tilting headstock with separate gun drilling and milling spindles, with fully automatic switchover requiring no operator intervention. ISO 50 milling spindle.

MF1250/2FL

Gundrilling and milling machine for middle-size molds with complex waterlines.

Headstock with separate gun drilling and milling spindle, fully automatic commutation.

Straight, single-angle and compound-angle drilling thanks to rotary/tilting table, load 6 tonnes.

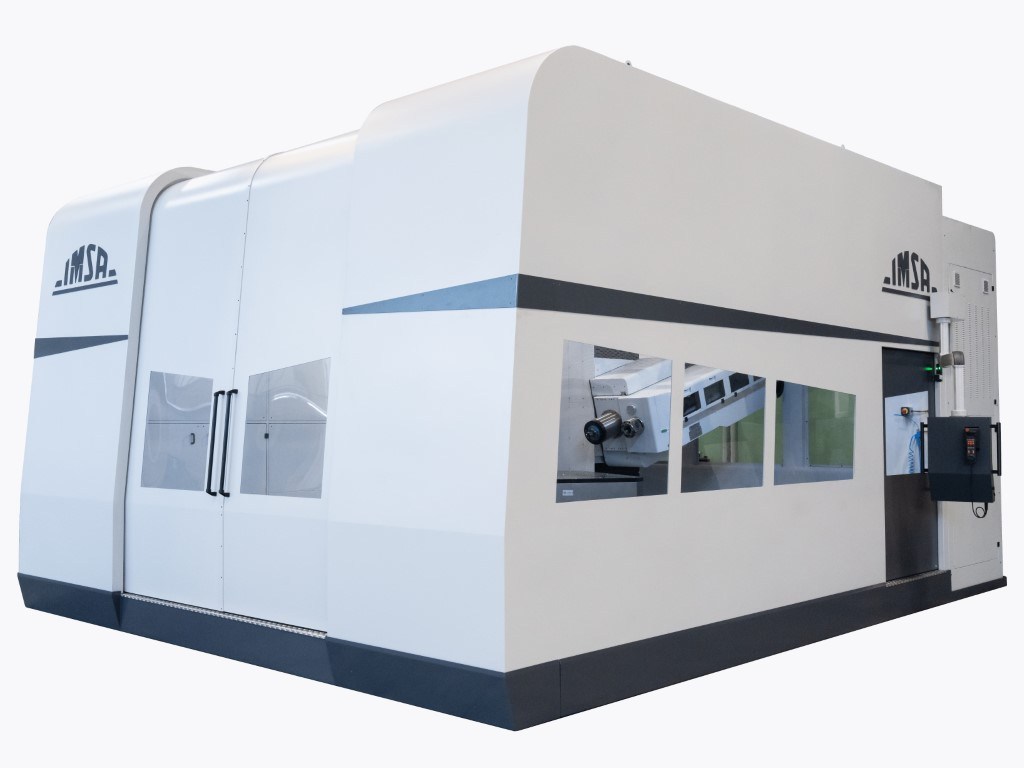

MF1600 S2

The milling and gun drilling center IMSA MF1600S2 is designed for manufacturers of tool and dies up to 30 tons in the mold making industry. T-shape machine concept: translating table and transversal movable column.

ISO50 35kW milling spindle. Two separate machining units, located on the same headstock carry out gun drilling and milling operations.

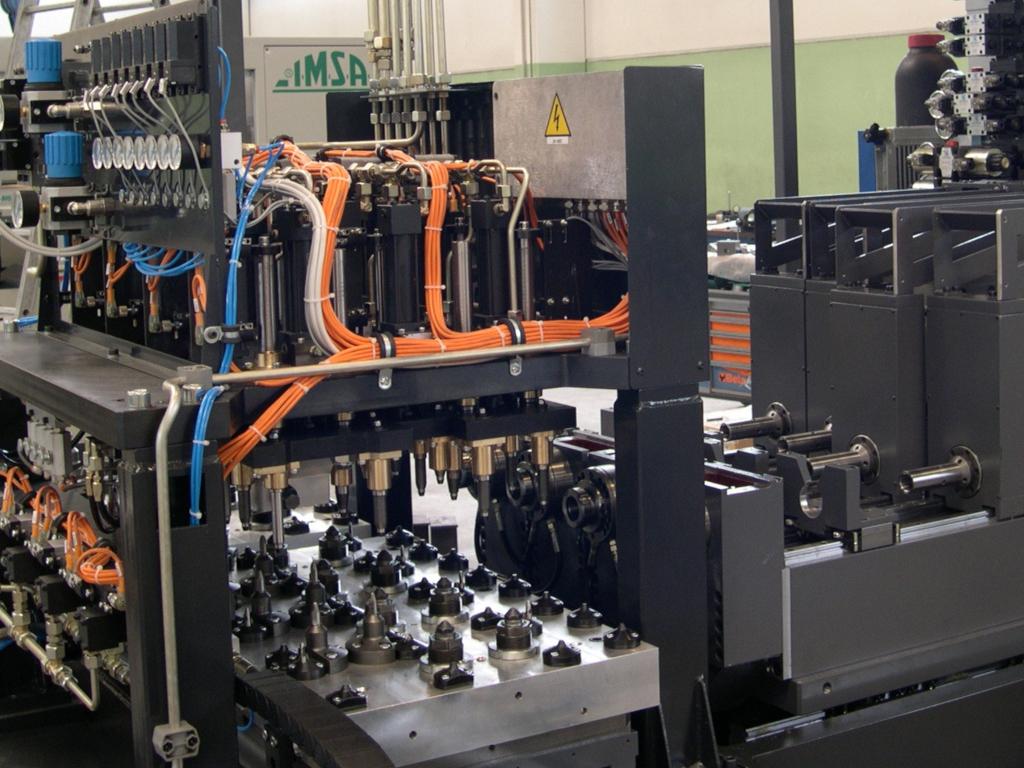

MF1300/4P EVO

“TOP AUTOMATION IN GUN DRILLING”: EVO-Series Gun Drilling and Milling center, equipped with IMSA’s 4-station Gun Drill Changer.

Tilting headstock with separate gun drilling and milling spindles, with fully automatic switchover requiring no operator intervention. ISO 50 milling spindle.

IMSA’s 4-station Gun Drill Changer enables automatic replacement of the gun drilling unit without operator intervention. Optional pallet changer.

MF1350 EVO

“GUNDRILLING AND MILLING IN SINERGY”: EVO-Series Gun Drilling and Milling Center for molds that require multiple-axis waterlines.

Tilting headstock with separate gun drilling and milling spindles, with fully automatic switchover requiring no operator intervention. ISO40 or ISO50 milling spindle.

MF1500 / 3000

Customized gun drilling and milling machine with increased horizontal travel.

MFT 750 /6 CR

Small diameter centerline deep drilling machine for cylindrical parts, especially for the medical industry. Single spindle. Method: by gun drill tool. Workpiece in counter-rotation. Drilling diameters: 1,5 – 6 mm. Drilling depth: max. 120mm approx. for Ø 1,5 – 3 mm; max. 750 mm for Ø 3 – 6 mm.

MFT 750 /12 CR

Centerline deep hole drilling machine for cylindrical parts, especially for the medical industry. Single spindle. Method: by gun drill tool. Workpiece in counter-rotation. Drilling diameter range: 3 – 12 mm. Dilling depth: (160 x Ø) max. 750 mm.

MFT 500CR – MFT 1000CR – MFT 1500CR

Centerline deep hole drilling machines. Single spindle. Drilling method: gun drill tool. Workpiece in counter-rotation. Drilling diameters: (4) 6 – 25 mm. Drilling depth max.: as per machine name, respectively 500 mm, 1000 mm, 1500 mm.