The I.M.S.A. MF1300/4P EVO deep drilling and milling center has a gun drill change system for changing 4 complete deep drilling units, an 80-position ISO50 tool changer and a two-position pallet changer.

Translation of the article by the technical journal MACCHINE UTENSILI (machine tools).

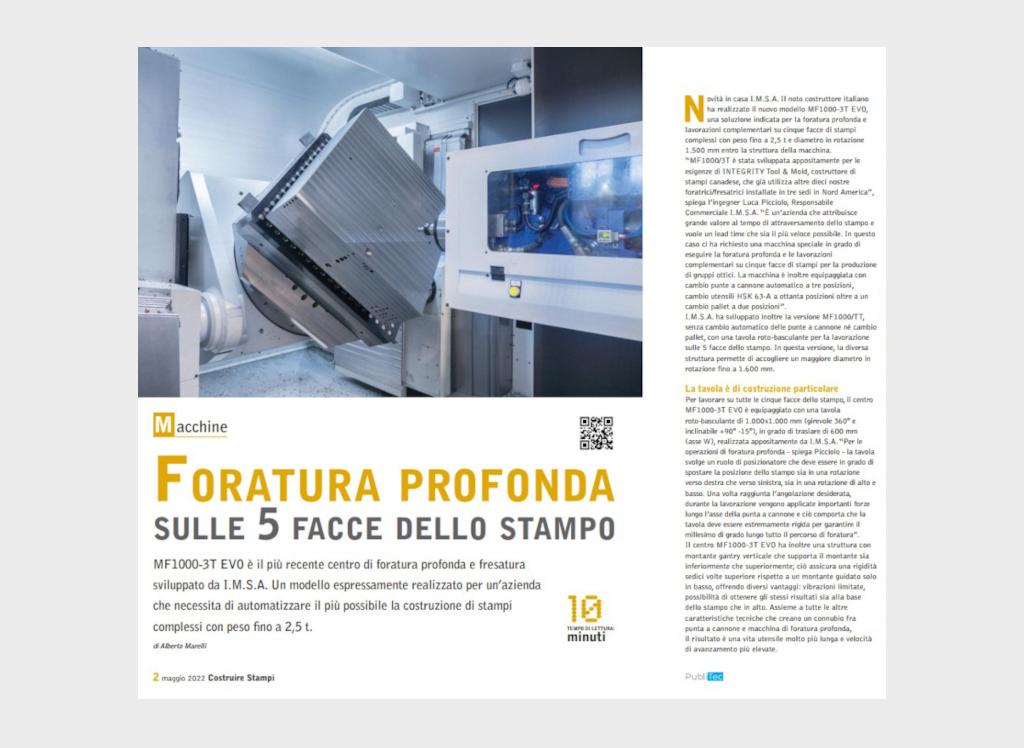

Among the latest machines produced by I.M.S.A. we find the deep drilling and milling center MF1300/4P EVO; main feature, the IMSA gun drill change system for the replacement of 4 complete deep drilling units, combined with an 80-position ISO50 tool changer and a two-position pallet changer.

This particular drilling machine has been commissioned by a Canadian manufacturer of moulds for the automotive sector, particularly demanding in terms of autonomy and reliability of the machine fleet. A mould-maker that already uses 9 other IMSA deep drilling and milling machines located in 3 sites in North America.

The IMSA gun drill change solution, first implemented in 2009, replaces 4 deep drilling units each consisting of a gun drill complete with chip box, nose bushing, steady rests and ISO50 spindle holder. This allows you to maintain proper constructional alignments and thus minimize vibration and increase straightness.

Why the gun drill changer? The choice of the IMSA solution is not related to the autonomy of the single gun drill tool, because drilling 30 – 40 meters in classic mould materials is already the norm on an IMSA deep drilling machine, before stopping to replace or sharpen the drill.

The choice of the “4P” which changes 4 gun drills automatically makes it possible to manage even 4 different diameters on the machine.

Combining a tool changer for ISO50 milling tools and a pallet changer, like on this production unit destined for overseas, means you can really work without an operator and be able to anticipate what you’ll need for the next job.

MACHINE SETUP IN DISGUISED TIME

What might this mean in a concrete case? For example, while the machine is working on a mould, the machinist can set up everything needed for the next mould that will be on the table in 6 hours, on which a conditioning circuit will have to be made with numerous deep double-tilt holes of a different diameter from the one we are currently working with, and a series of complementary machine operations of various types with the tools we are already preparing in the ISO50 tool changer, and clamping the next mould on the second pallet changer station. All in complete safety.

In fact, both the gun drill changer, the ISO50 tool changer and the pallet changer are specially arranged in separate areas sheltered from the machine’s working area. A machinist who is in charge of several production units will therefore be able to systematically organize the next working hours in advance, while this machine is already working autonomously.