Technical Solutions To Mill On IMSA Gundrill Centers for Molds

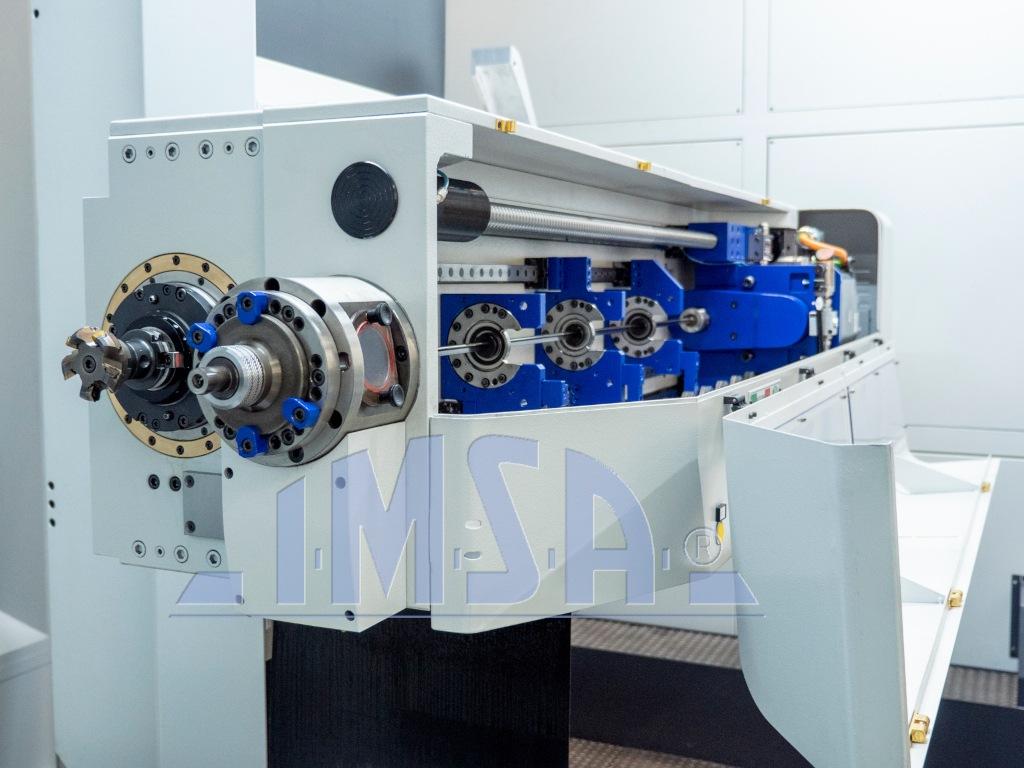

IMSA’s dual spindle concept sees on the same headstock a gun drilling spindle and a milling spindle for other machining operations such as face milling, spot-facing, tapping,… Our gundrilling and milling machines for molds adopt different technical solutions for switchover drilling/milling and back.

The advantages of the dual-spindle, in deep drilling and milling

The already wide and diversified range of deep drilling machines designed and manufactured by IMSA can now count on a new model for parts up to 4 tonnes, featuring a dual-spindle configuration to ensure uncompromising productivity and versatility for mould makers. Article of the Italian technical magazine STAMPI.

User report: SANVITO & SOMASCHINI – A landmark in the automotive industry

Sanvito & Somaschini is an Italian company specialising in the mold making for the construction of plastic parts for the automotive industry. In cooperation with I.M.S.A., the company realized an efficient and optimized deep drilling cell. Article of the Italian technical magazine COSTRUIRE STAMPI.

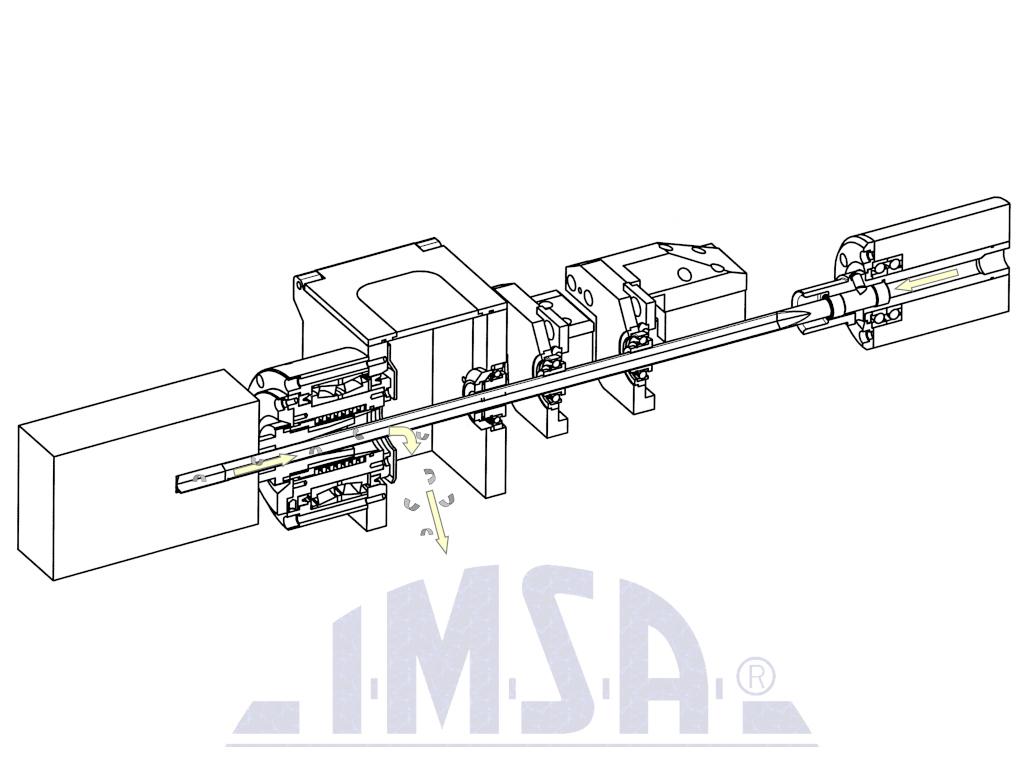

The Deep Drilling Process

A hole is defined as deep when the length of the hole exceeds at least 10 times the diameter of the tool, up to lengths of 150 times the diameter and more, depending on how the tool is guided through the machine. This is such an extensive range that it includes different systems and tools: helical drills, gun drills, BTA/STS tools.

Deep hole drilling on the 5 faces of the mold

MF1000-3T EVO is the latest deep hole drilling and milling center developed by I.M.S.A., expressly made for INTEGRITY TOOL & MOLD, a company that needs to automate as much as possible the construction of complex molds weighing up to 2.5 t. – Article from the Italian technical magazine “COSTRUIRE STAMPI”.

User Report: R.S. MECCANICA – Increasing Efficiency in Deep Drilling

Specialized in the construction of injection moulds for the automotive sector, R.S. MECCANICA realizes the cooling circuits of the moulds on deep hole drilling machines of the Italian manufacturer I.M.S.A. Last year, R.S. Meccanica purchased the MF1300/4P EVO model from I.M.S.A., equipped with a 4-position drill changer and 60-position milling tool changer. – Article of the Italian technical magazine COSTRUIRE STAMPI (mold making).

Automate DEEP DRILLING to the maximum

The I.M.S.A. MF1300/4P EVO deep drilling and milling center has a gun drill change system for changing 4 complete deep drilling units, an 80-position ISO50 tool changer and a two-position pallet changer. Article by the Italian technical magazine MACCHINE UTENSILI (Machine Tools).

User Report: CLAREN TOOLS – Large moulds: complex deep drilling and milling on behalf of third parties

Claren Tools has expanded its fleet of machines by integrating a new IMSA deep drilling and milling center. A new strategic investment oriented to increase the production capacity of the company, as well as to provide an additional service of contract machining. Translation of the article of the Italian technical magazine STAMPI

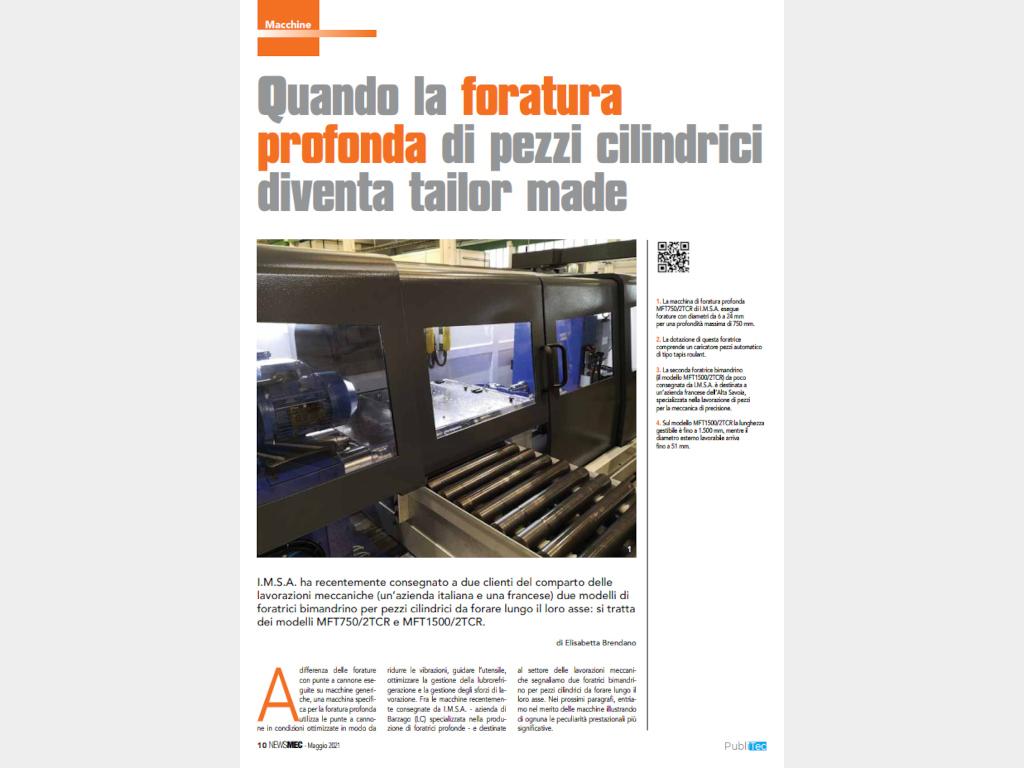

When deep drilling of cylindrical parts becomes tailor made

I.M.S.A. has recently delivered two models of twin-spindle gun drilling machines for cylindrical parts to be drilled along their axis to two customers in the machining sector (an Italian and a French company): these are the MFT750/2TCR and MFT1500/2TCR models. Article of the technical magazine NEWSMEC.

User Report: MOULD SOLUTIONS – Technology makes the difference

Mould Solutions has been operating in Maniago, in Friuli Italy, for over forty years. It is a dynamic company specialising in the design and manufacturing of injection moulds for plastics and thermosetting materials. The company relies on the MF1250/2FL gun drilling machine from Italian manufacturer I.M.S.A. to make the cooling circuits for the moulds. Translation of the article published by the Italian technical magazine “Costruire Stampi”.

Axial deep drilling of custom sized cylindrical parts

Two I.M.S.A. MFT deep drilling machines, supplied to corporate clients this year between June and July, feature some improvements which the manufacturer highlights by adding the code EVO to the machine name. One model was built for a French tool manufacturer, while the other one was developed for an Italian company operating in the aeronautical field. Translation of the article published by the Italian technical magazine “NewsMec”.

[Interview] Responses tailored to customer needs

A dynamic reality where each design is a tailored response to customers who need precision and speed in deep drilling. Sales manager for I.M.S.A. srl, Luca Picciolo, tells us about the current situation in our interview with him. – Translation of the interview carried out by the Italian technical magazine “Macchine Utensili”

MF1350EVO: Innovations that anticipate mould-maker needs

Over the last few years I.M.S.A. has renovated its entire range of mould and block deep drilling machines and, notably, it has developed the new MF1350EVO model, a deep drilling and milling machine designed for machining moulds weighing up to 12t. Translation of article from the Italian technical magazine “Costruire Stampi”.

User Report: EXACTA STAMPI and IMSA – The New Era of Deep Drilling

Precision, flexibility, power: these are the key features of the new drilling and milling centre just launched on the market. Ideal for the mould industry. Translation of article published in the Italian technical magazine “Stampi”.

500th IMSA Gundrill delivered

14/11/19 We are pleased to announce the installation of our 500th deep hole drilling machine.

User report: OFBM MOULDS – Quality and experience at the service of customers

Professionalism and experience, high quality materials, innovative solutions, accurate execution, timely deliveries and, above all, great passion allowed OFBM MOULDS to operate in the global market. For deep drilling operations the company relies on the solutions from Italian manufacturer I.M.S.A.

Translation of the article published by the Italian technical magazine “Costruire Stampi”

User Report: S&S Werkzeugbau, Schlitz – Deep drilling and milling of mold plates

With the IMSA MF1000C deep drilling machine, German mold manufacturer S&S achieved significant improvements in their production process of mold plates. Translation of article that appeared in the German industrial magazine NC FERTIGUNG, May 2019

IMSA – Specialists in Deep Drilling for 30 Years

Every important anniversary is a time to reflect on the milestones reached and goals yet to be achieved. For IMSA’s 30th year in operation, Italian trade magazine COSTRUIRE STAMPI (mold making) interviewed Luca Picciolo, Sales Manager, who retraced the milestones of the company’s growth and forecasting future scenarios for deep drilling.

30 Years in business – Specialists in deep drilling and complementary processes

In its first 30 years in business, IMSA has consolidated its position as a key player at national and international level. With a range of high-performance and customized drilling and milling machines for molds and blocks, machines for the centerline drilling of cylindrical workpieces, as well as special machines.

User Report: COPY – Abreast of New Technologies

COPY is a contractor company based in Brescia that performs rough machining, deep hole drilling, finishing on dies and punches as well as on particular for molds. For deep drilling operations, COPY relies on solutions provided by the Italian manufacturer I.M.S.A. Translation of article that appeared in the trade magazine COSTRUIRE STAMPI – May 2018

User report: ALBA – Passion and expertise serving major mold manufacturers

Specialists in the manufacture of ground plates, standard mold bases, special mold bases and technical equipment according to customer specifications, ALBA has introduced a new deep hole drilling and milling machine for molds made by IMSA. Translation of the article published by the Italian technical magazine “STAMPI” (Molds) March 2018

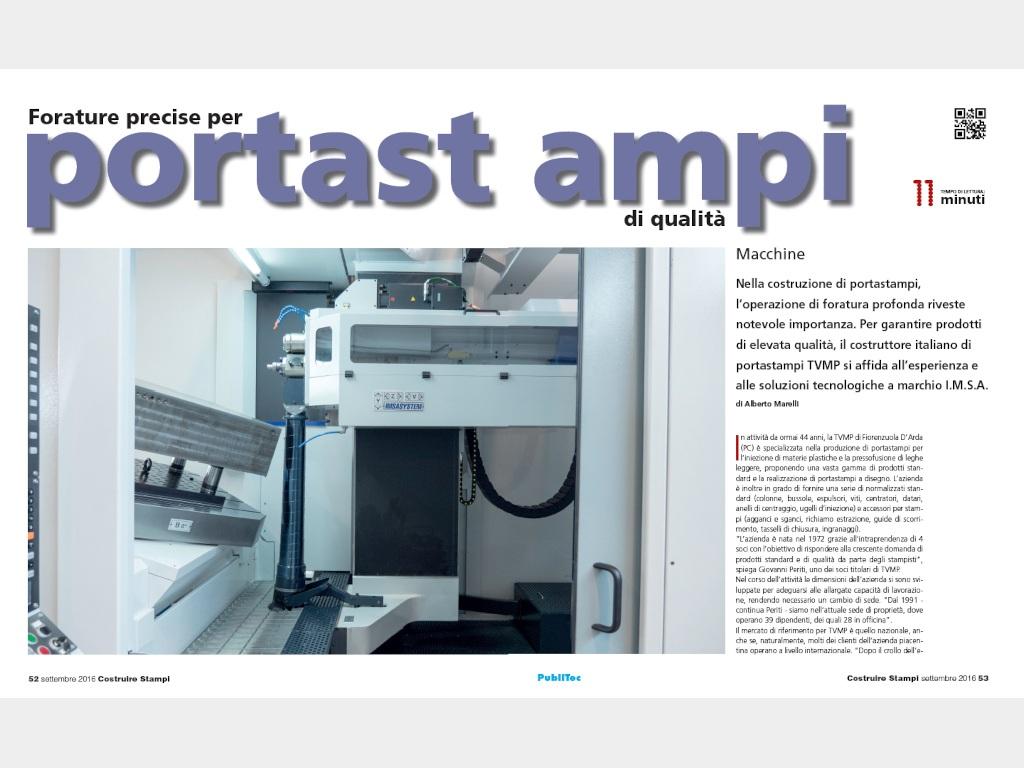

User report: TVMP – Precision drilling for top quality mold bases

One of the most critical operations in manufacturing mold bases is deep hole drilling. To ensure a high-quality product, TVMP, an Italian manufacturer of mold bases, relies on the experience and technological solutions of I.M.S.A. Translation of article by the Italian technical journal “COSTRUIRE STAMPI”

User report: KANTEMIR – Gundrilling becomes multitasking

The latest machine by IMSA is a winning solution for manufacturers of multiple molds, offering significant capacities not only in gundrilling, but also in milling and process management.

MF1300BB/4P presentation at EMO trade show

“Top-Automation in gundrilling” – Presentation of deep drilling center with gundrill changer – EMO Milano 2015

The Vertical Gantry column of IMSA gundrilling machines

Many IMSA machines for molds and blocks have a Vertical Gantry Column structure. This means, the column is supported and guided at both bottom and top.

Gundrilling and milling for large molds – IMSA MF1500BB/6P

World-class automation, flexibility and safety without compromise: These are the main features of the new machine made by a well-known manufacturer in Lecco (Italy), recently purchased by a Canadian mold company for their manufacturing facility.