Specialists in the manufacture of ground plates, standard mold bases, special mold bases and technical equipment according to customer specifications, Alba has introduced a new deep hole drilling and milling machine for molds made by IMSA. Integrating these process technologies has enabled the company to expand its production capacity and sharpen its competitive edge.

Translation of the article published by the Italian technical magazine “STAMPI” (Molds) March 2018

Founded in 1989, Alba is a family-owned business specialized in machining for the mold and die industry. A team of some 30 highly skilled people work at the 2,000 square meter production facility, located in San Vittore Olona (MI), that has a diverse and extensive range of machinery.

A passion for mechanics and understanding customer needs has allowed the company to evolve rapidly, keeping in pace with leading mold manufacturers.

“Our company,” explains owner Domenico Rossi, “provides custom designed ground plates, mold bases, technical equipment and standard components. Our products are used in injection molds for thermoplastics, molds for aluminum die cast parts, and metal punching dies.”

Alba mainly serves customers in the automotive and household appliance industries, both in Italy and abroad.

“We export about 30% of our production to Germany,” says Mr. Rossi, “a percentage set to rise as part of our development strategy, in pace with our increasing production capacity. Having said that, we will continue, as always, to dedicate maximum attention and resources to our main objective, maintaining the highest possible quality product.”

In this regard, the company’s longstanding commitment to investing in technological upgrades plays a crucial role.

The company recently purchased a new deep hole drilling and milling machine for small and medium-sized molds and dies from I.M.S.A. in Barzago (LC).

FROM DRILLING TO MILLING

“The decision to buy a new drilling machine,” notes Mr. Rossi, “was prompted by specific production requirements, namely to meet the increasing demand of customers to further speed up the drilling process, especially for injection mold components.”

The company, after addressing the issue with a quick fix (modifying a machine by adding a deep hole drilling unit), identified IMSA as a qualified partner which they could rely on to meet their needs.

“After discussing the technical issues with Mr. Luca Picciolo (sales manager at IMSA),” continues Mr. Rossi, “the MF1000C model was determined to be the best solution for our primary operational requirements.”

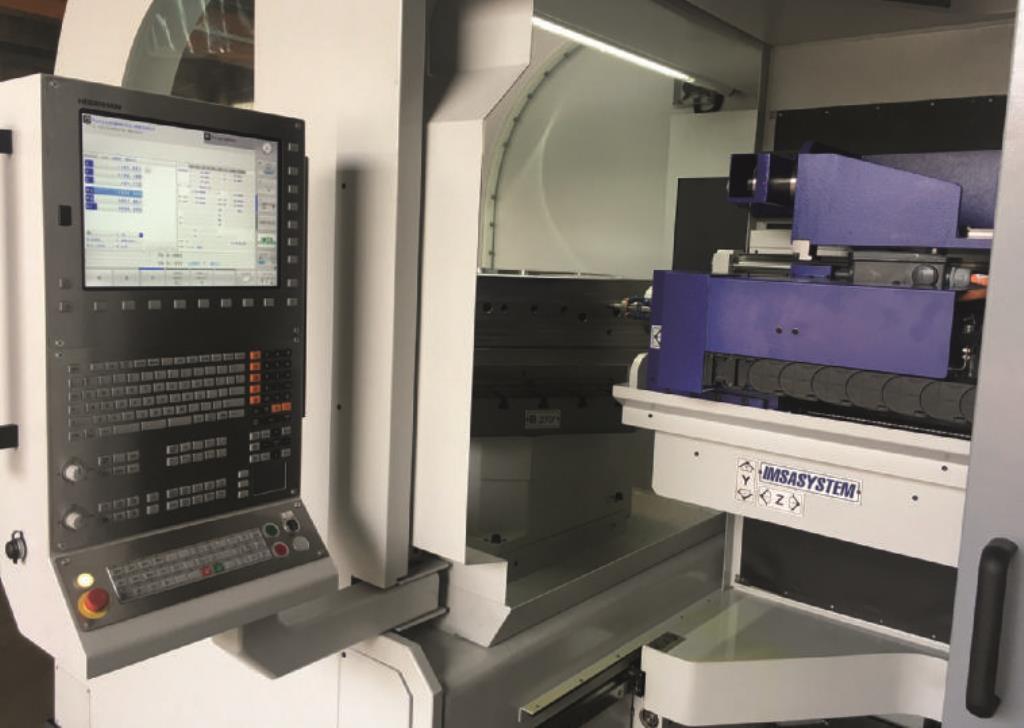

The MF1000C is a compact deep drilling/milling machine for mold inserts, small molds, and other workpieces. It can also be used to drill off-center deep holes in cylindrical parts. It features a horizontal X-axis of 1000 mm, a vertical Y-axis of 520 mm, a maximum drilling depth of 1000 mm, for optimal drilling diameters from 4- 25 mm solid. It can be equipped with various types of tables, based on the machining geometries required: rotary/tilting tables with load capacities of 2 or 4 ton (like the one Alba chose), or with rotary/tilting tables (tilting angle +25°-20°) with a load capacity of 2 ton.

A distinctive feature of the machine is, without a doubt, the vertical gantry structure that provides excellent rigidity; the gantry column is designed to ensure top performance in any position along the Y-axis.

“From a practical standpoint,” observes Rossi, “this means we can complete drilling without interruption, due to it having a tool life of more than 20-30 meters of drilling. An added bonus is the possibility to perform milling operations for roughing and finishing holes. Applications include spot-facing, twist-drill boring or tapping operations.”

The IMSA technical team has designed and manufactured an innovative system for changing operations: the Swing On Top Imsasystem. With this system, the machinist can switch between deep drilling and milling operations without having to disassemble/reassemble any machine parts. The gun drill head is composed of ISO40 taper, steadyrests to guide the gun drill along its length and frontal head with chip box. The exclusive system rotates the complete drilling unit towards the top and sets the liquid-cooled spindle free for milling operations. In the milling configuration, the spindle is located in the front part of the headstock, and the headstock is moved towards the workpiece.

CONSTANT, UNCOMPROMISING QUALITY

Thanks to the integration of the new IMSA deep hole drilling/milling machine, Alba has further increased its production capacity.

Mr. Rossi says, “The equipment at our facility allows us to work on mold bases measuring up to 1500 x 2000 mm. This is why, also in view of the fact that we are very happy with our purchase, we plan on introducing a new IMSA drilling machine in the future, in order to cover our needs with a dedicated machine offering a wider operating range. At present, we are able to perform these operations in-house using a machine equipped with a generic, non-specific drilling unit. While this does not affect the level of quality, a new machine would most certainly speed up the processes.”

As already mentioned, ensuring process and product quality is crucial for the company.

“Leaving aside the fact that we are ISO 9001 certified,” continues Mr. Rossi, “we take care of all details in the development of each order: from toolpath generation in the office, to controlling the raw material and all the necessary stages of processing, inspected and tested also using the coordinate-measuring machines at our facility.”

Quality assurance is a must considering the increasingly strict requirements of the company’s target market: the automotive industry.

“After some 30 years in the business,” adds Mr. Rossi, “we are confident that world of mold manufacturers recognizes us as a dependable, reliable and qualified company that delivers quality products.”

A mission that has not only made it possible for the company to push through the hard times of recent years, but also to look to the future with the confidence and awareness that it has what it takes to continue growing. In response to the positive trend, Alba expanded its production area by an additional 400 square meters last year. The company also stands out for the attention it devotes to human resources, training and the professionalism of its staff.

“I believe that these are all key elements in being able to meet the high standards of quality demanded by our customers and to be increasingly competitive in meeting market demands,” concludes Mr. Rossi. “Completing our transition to Industry 4.0. will be a challenge for our future. We started this transition some time ago in our business management and work scheduling systems, as well as in monitoring various activities at our facility.”